For fertilizer entrepreneurs aiming to invest in a 20 T/H NPK blending plant, understanding the cost factors is essential. As a leading NPK fertilizer equipment manufacturer, the major cost to build a 20 t/h NPK mixing factory includes equipment selection, factory layout, land, labor, infrastructure, and raw material purchase. Indeed, our company offers an economical plan for a 20 T/H bulk blending fertilizer production line, with a budget ranging from $60,000 to $80,000. Additionally, we provide a more complex NPK fertilizer production line based on dry granulation technology. Whatever, we can offer actionable insights for your 20 TPH bulk blended fertilizer business plan.

How Much to Invest A 20 T/H BB Fertilizer Production Line?

Typically, customers seeking to build a compound fertilizer plant with limited budget need a reasonable NPK fertilizer production line. Also, such fertilizer manufacturers aiming for higher capacity benefit significantly from BB fertilizer production technology. Therefore, you should not worry about the budget, because our bb fertilizer production process is simple and cost-effective. Our basic 20 t/h BB fertilizer mixing line requires equipment ranging from batching, mixing to packaging. And the total equipment cost estimate for 20 T/H bb fertilizer production plan is $60,000–80,000 USD.

20 TPH NPK Fertilizer Blending Process

- 1

Firstly, the batching system accurately ensures NPK ratios, with a four-bin batching machine costing around $8,000-$12,000. Moreover, it weighs and proportionally feeds different raw materials for precise NPK blending.

- 2

Secondly, we select drum type bb fertilizer mixer blends NPK ingredients uniformly for large scale manufacturing of 20 t/h capacity. In addition, its price is at $12,000-$15,000.

- 3

Thirdly, elevators and conveyors transport NPK granules efficiently, costing $5,000-$8,000.

- 4

Fourthly, dust collectors and auxiliary devices maintain a clean environment, costing $3,000-$5,000.

- 5

Fifthly, our automatic packaging machine allows efficient bagging and sewing, increasing packaging efficiency by 40%, priced at $12,000-$16,000.

- 6

Additionally, a silo storage system holds 50-100 tons of finished BB fertilizer granules, with the price of $14,000-$15,000.

- 7

Finally, there are plus installation, automation, and auxiliary systems such as PLC system adding $10,000-$15,000 to the bb fertilizer plant equipment cost.

In conclusion, with our efficient equipment and NPK blending technology, you can establish a 20 T/H BB fertilizer production line within a reasonable budget.

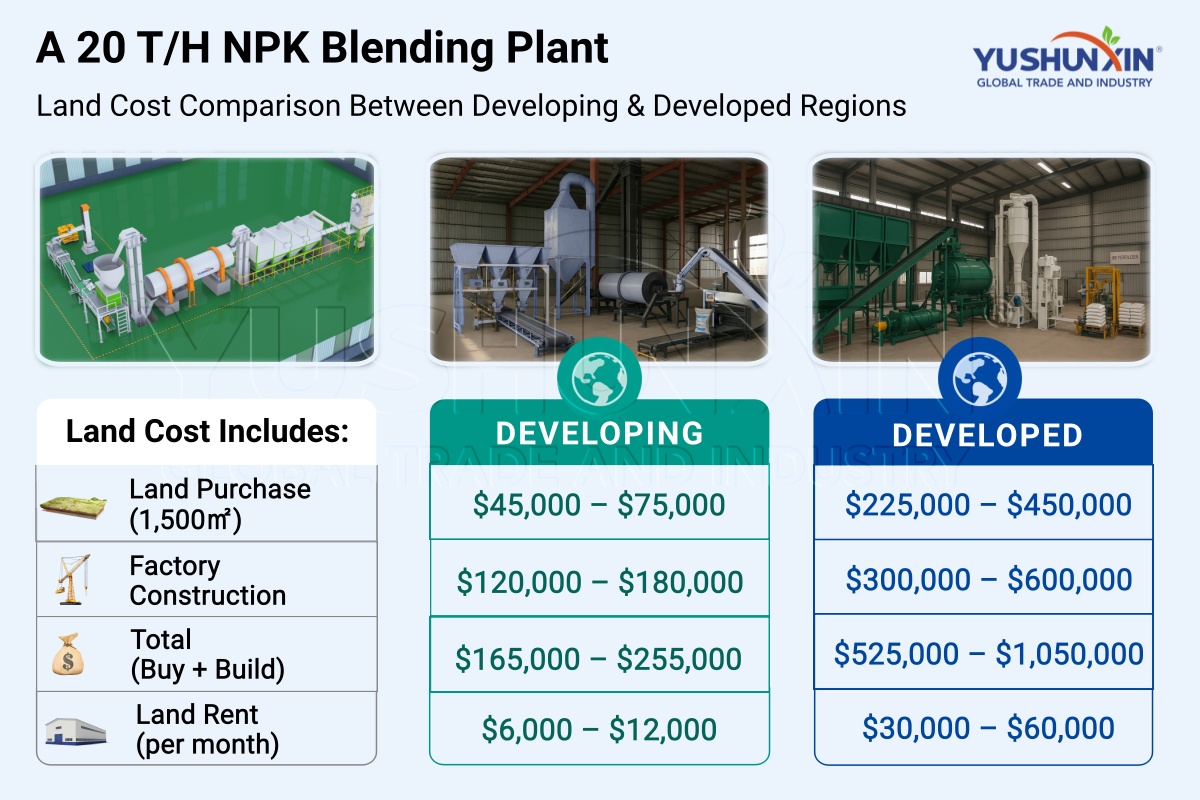

What Are the Land And Factory Construction Costs for A 20 T/H NPK Blending Plant?

Land cost includes land purchase or rent, plus facility construction and legal permits for your BB fertilizer production line.

In practice, the total cost for land and civil engineering of your 1,500㎡ NPK blending fertilizer factory may range from $165,000 to over $1 million. You can contact us for how to set up a 20 t/h bulk blended fertilizer manufacturing line layout.

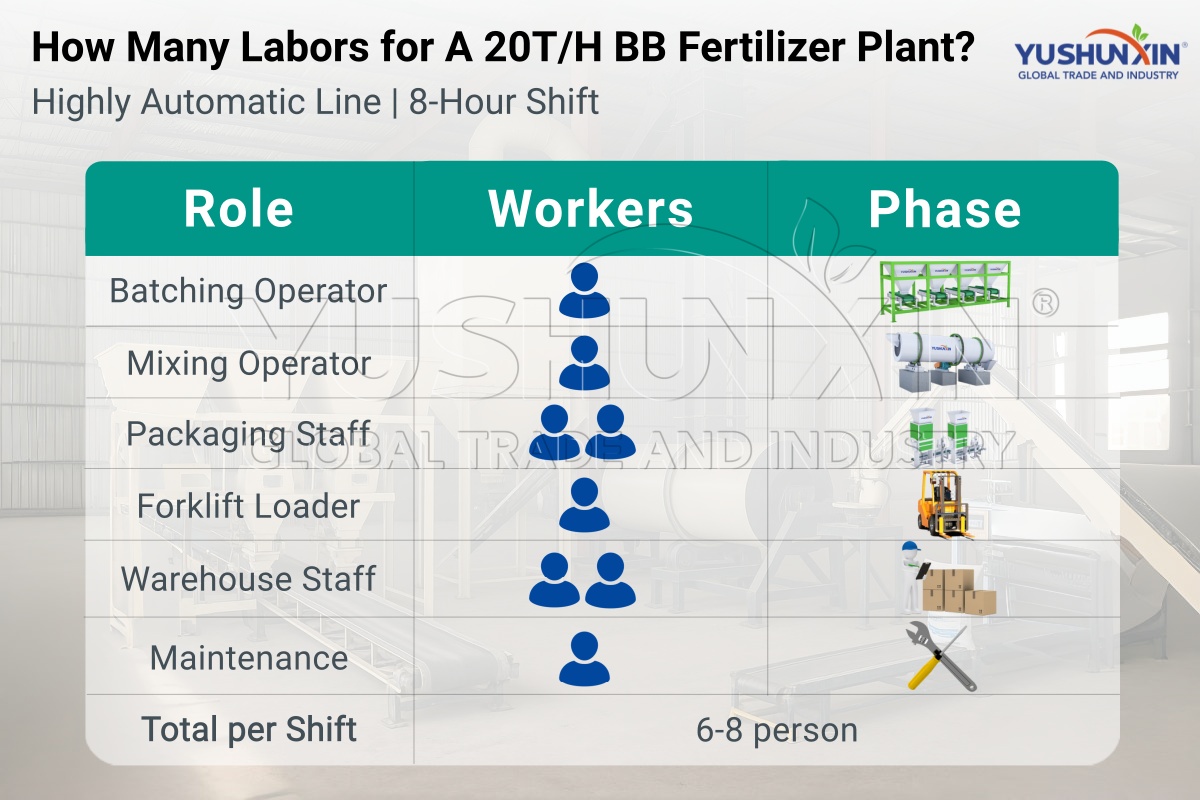

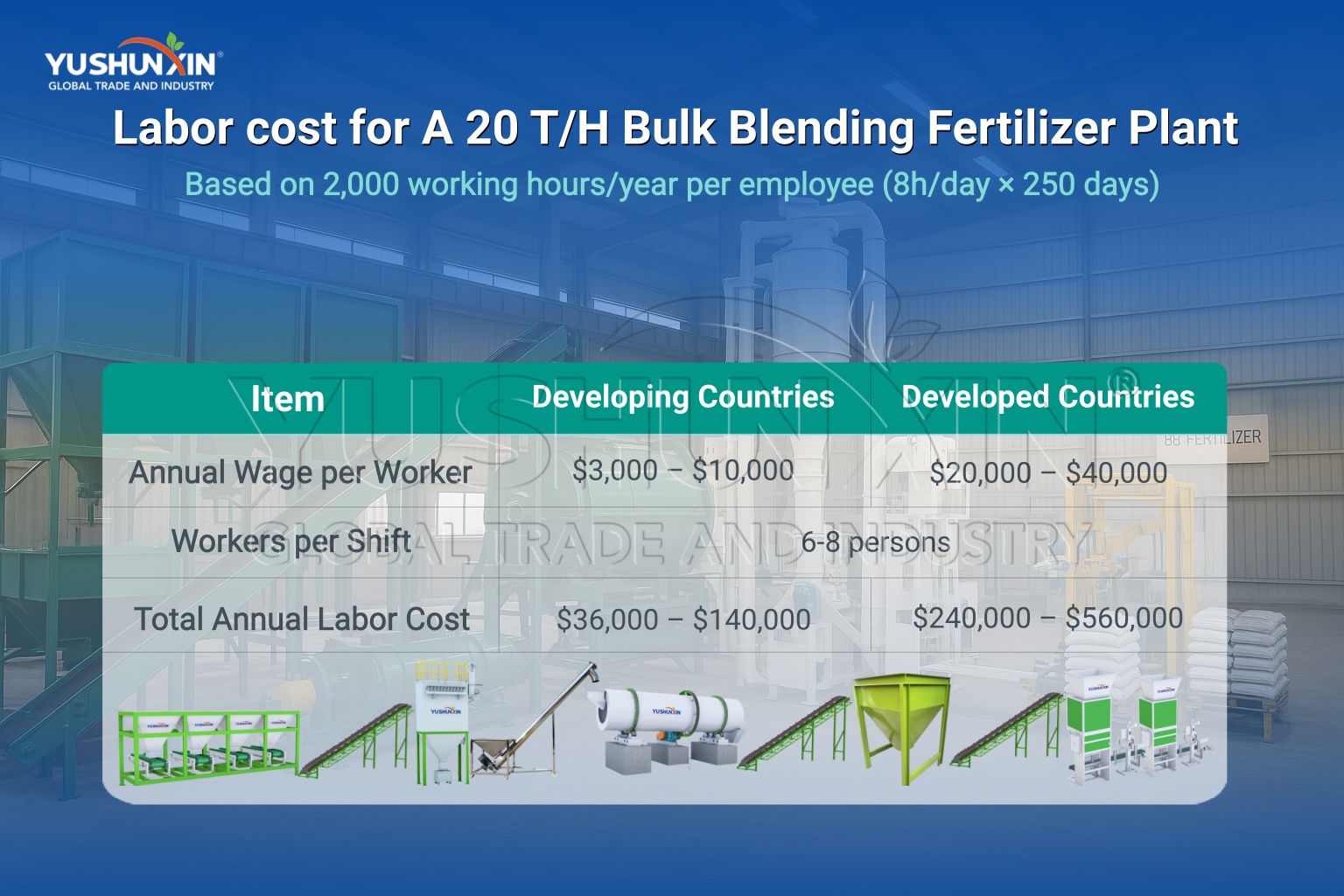

What Is The Labor Cost for 8 Workers in A 20T/H BB Fertilizer Plant?

We suggest a highly automatic BB fertilizer production line, because the labor cost is not high. In general, an 8-hour shift in your 20 t/h bulk blending fertilizer production plant may require about 6-8 workers. Specifically, one worker handles the batching of the NPK blending fertilizer manufacturing process, and another oversees the mixing stage. Additionally, two workers manage packaging 20 t/h bb fertilizers. One operates the forklift loader. Furthermore, two are in charge of the warehouse. Moreover, there is one maintenance person for your bulk blending fertilizer equipment.

Based on a work schedule of 8 hours per day for 250 days, each employee works 2,000 hours annually. For instance, in developed countries, the annual wages per person in 20 t/h bb fertilizer plant range from $20,000 to $40,000. While in developing countries, you need to pay one worker’s salaries varying from $3,000 to $10,000 per year. Therefore, we estimate the total annual 20 TPH BB fertilizer plant labor cost at $240,000-$560,000 for developed markets, and $36,000–$140,000 for developing regions.

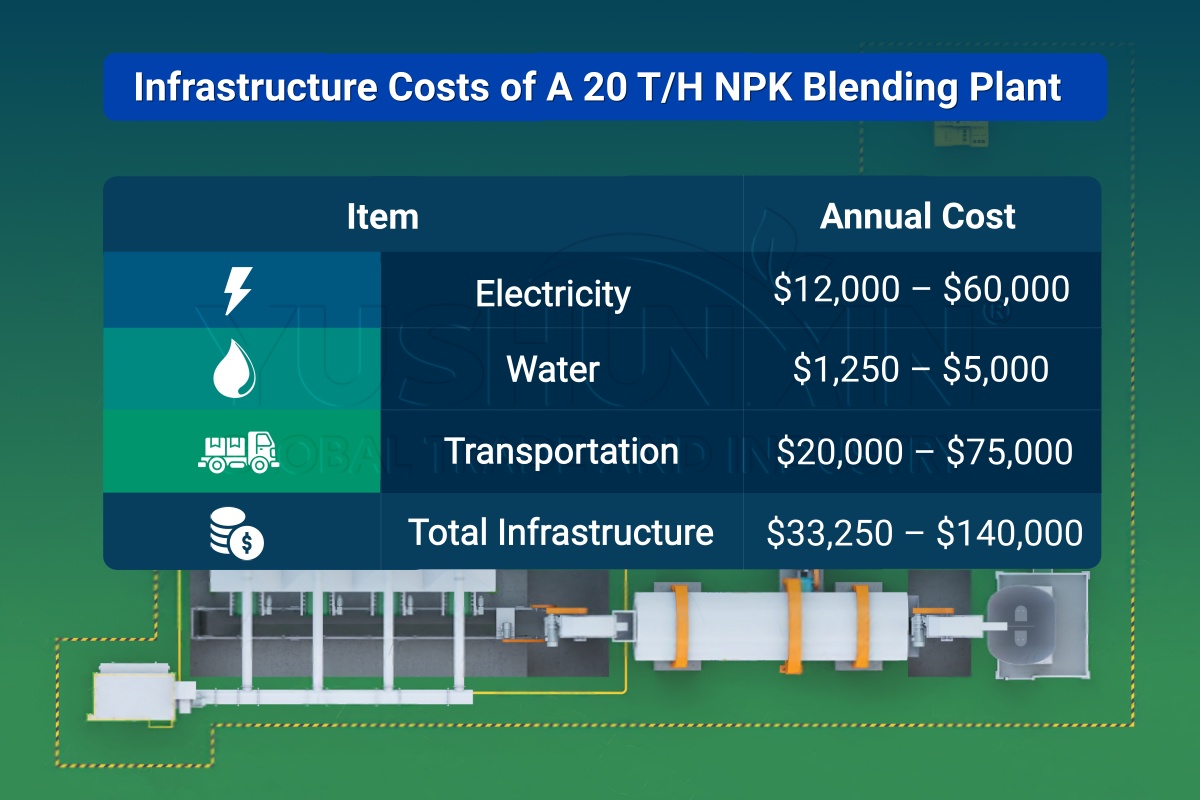

What Are The Infrastructure Costs for A 20 T/H NPK Mixing Factory?

When planning a 20 t/h BB fertilizer plant, you should more care about total power, electricity expenses, water charges, and transportation fees. Typically, our 20 t/h bb fertilizer production line may consume 100-150 kW/h electricity. If you run the NPK blending factory for 8 hours daily and 250 days yearly, your total power usage is 200,000-300,000 kWh per year. Since industrial electricity prices differ by country, your annual electric bill may range from $12,000 to $60,000. Additionally, because bb fertilizer mixing uses little water, our company estimates water costs of 20 t/h bb fertilizer plant at $1,250-$5,000 per year. Also, you should prepare transportation costs for raw materials and finished NPK blended fertilizer, which can be $20,000-$75,000 annually, depending on local logistics prices.

How Much Are 20 TPH NPK Blended Fertilizer Plant’s Raw Material Cost?

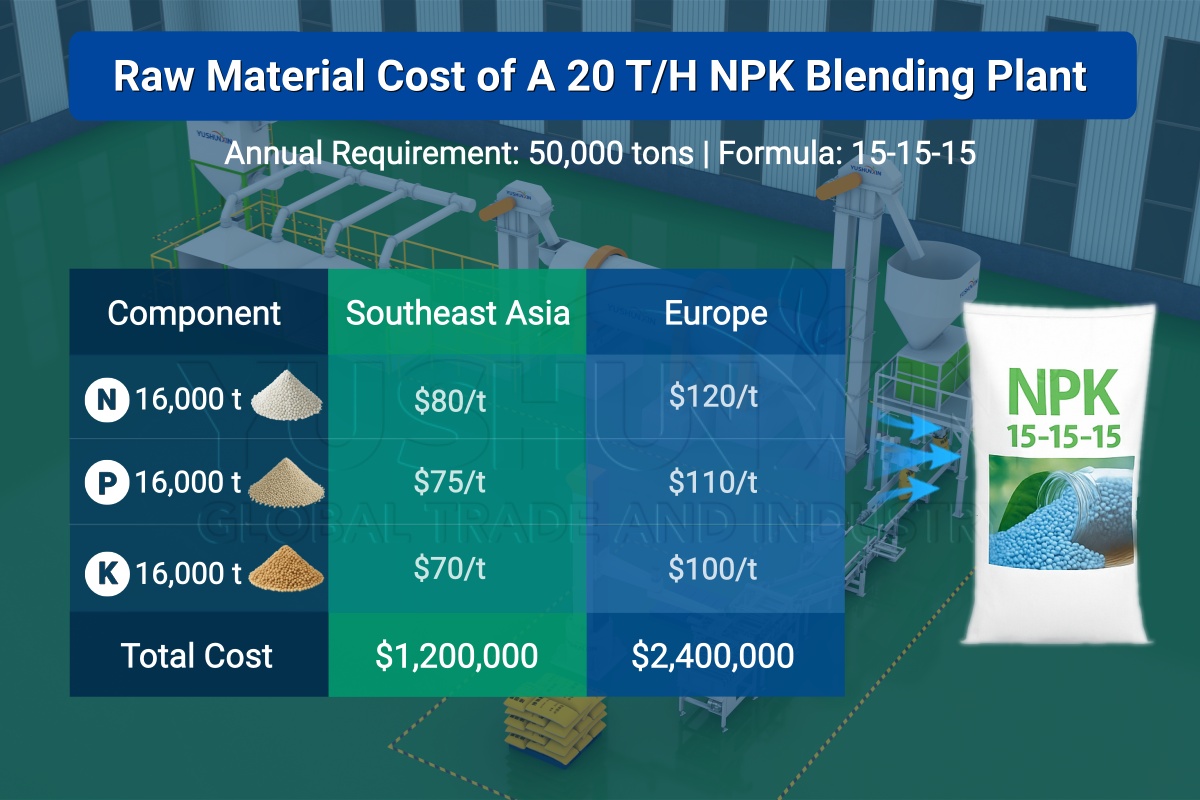

If you run a 20 t/h bulk blending fertilizer production line, you need to process about 50,000 tons of bulk fertilizer granules annually. For example, a typical NPK blended fertilizer formula, 15-15-15, requires equal parts of nitrogen, phosphorus, and potassium granules. In other words, you need to reach annual npk fertilizer blending requirement about at least 16,000 tons each for N, P, and K components. In Southeast Asia, nitrogen fertilizer granules cost $80/ton, phosphorus fertilizer pellets are $75/ton, and potassium fertilizer particles reach $70/ton. Thus, clients need to spend about $1,200,000 per year on raw materials of 20 t/h bb fertilizer factory in this region. However, in Europe, the total NPK raw material costs raise to about $2,400,000. In average, fertilizer manufacturers may pay $120, $110, and $100/ton for N, P, and K particles. Additionally, bulk fertilizer granules suppliers offer price variations. Choosing the right NPK fertilizer raw material cost structure helps you optimize BB fertilizer production cost and overall fertilizer mixing plant cost.

In summary, investing in a 20 t/h NPK mixing factory requires a comprehensive understanding of all related costs. Moreover, careful planning remains crucial for balancing equipment, land, labor, infrastructure, and raw materials. While costs vary by region, efficient equipment and optimized processes can help control expenses. Furthermore, selecting reliable suppliers and adopting automation further enhance profitability. Ultimately, a clear budget and expert guidance will support your successful entry into the NPK fertilizer industry.

Get Free Quote Now!