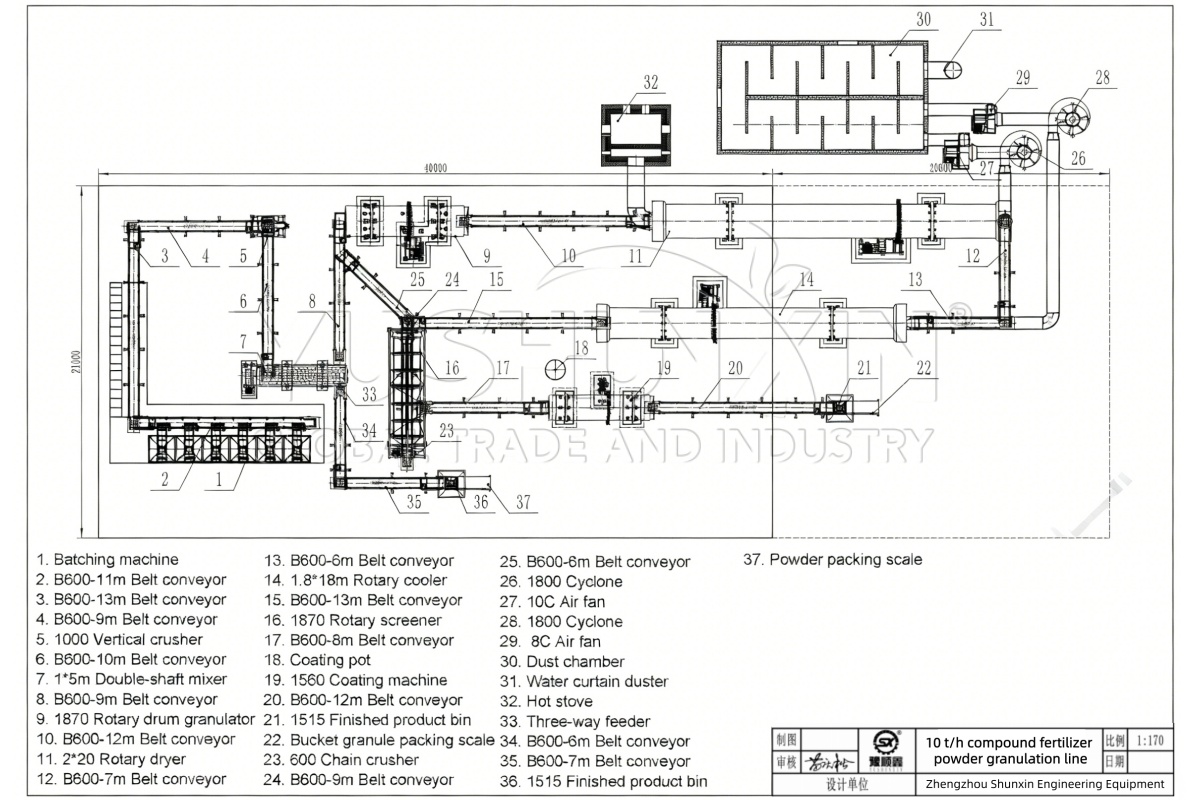

Our company designs and manufactures a 10 TPH compound fertilizer granulation line for medium and large fertilizer plants. This wet granulation system processes raw NPK materials into high-strength granules or pellets, and the workshop usually covers around 1,400-1,500 ㎡. Bovendien, we provide two npk fertilizer pellet production solutions for different investors, including design, manufacturing, installation, and commissioning. Eigenlijk, the entire compound fertilizer production line integrates reliable wet granulation technology, stable process control, and efficient packaging systems.

2 Types Compound Fertilizer Granulation Projects with Budget of USD 200,000-250,000

Our company provides two professional project plans for 10 TPH compound fertilizer granulation. Each system features different configurations, layouts, and cost-performance advantages.

Plan A: Dual-Function 10 TPH Compound Fertilizer Production System

This plan produces both powder and granular compound fertilizers. It includes a full range of machines like dynamtic batching system, vertical crusher, coating drum, powder screening machine and powder packaging machine. Bovendien, the structure is flexible and suitable for diverse market demands and export operations. And the equipment investment reaches USD 220,000-250,000. In werkelijkheid, the layout of 10 tph powdery and granular compound fertilizer manufacturing line occupies about 1500 ㎡. Beside, its total power consumption is 350-380 kW, requiring around 280-300 USD per day for electricity (based on 0.12 USD/kWh). Dus, this design suits multi-product compound fertilizer plants seeking high output and faster return.

Plan B: Simple 10 T/H NPK Fertilizer Granulation Line

This layout focuses only on NPK fertilizer pellet production. Alternatively, the feeding machine replaces the batching system, and supplies NPK powders directly into drum granulator. To reduce compound fertilizer plant investment, it omits crushing powder and coating steps. In aanvulling, this 10 t/h compound fertilizer wet granulation system layout requires around 1200 ㎡ land, and investment remains USD 180,000-200,000. Verder, its energy consumption is 230-250 kW, costing about 180-200 USD per day for electricity. Although the simple npk fertilizer pellet production line reduces cost but still ensures stable wet granulation performance.

Samengevat, both options support wet granulation technology and can process urea, KAART, DAP, and KCl materials efficiently. 10 TPH compound fertilizer powder & granule production line offers higher flexibility, while a single NPK fertilizer drum granulating line favors cost control.

How Does The 10 T/H Compound Fertilizer Manufacturing Process Work?

the compound fertilizer production process maintains efficient and clean operation from raw material feeding to final packaging. And each NPK fertilizer machinery controlled by PLC automation for stable operation and product quality.

Dus, this 10 t/h wet granulation process achieves uniform size and stable storage performance for every NPK fertilizer pellets batch.

Main Granulation Equipment Selection for 10 TPH NPK Fertilizer Plant

Granulator selection directly affects output rate, granule quality, and plant investment. We recommend two main models according to customer demand for different capacity and budget targets.

When clients compare both options, the drum granulator fits large‑scale compound fertilizer plants requiring continuous high yield. The disc granulator fits small and middle investors who prefer simple operation and low energy consumption. Both granulators use advanced wet pelletizing technology to produce 10 t/h NPK fertilizer granules. Ook, each granulator works well within a comprehensive 10 t/h compound fertilizer manufacturing process including feeding, mengen, granulating, drying, and packaging. Our technical team helps clients design the proper granulation system layout and choose auxiliary equipment such as dust collectors, coolers, or coating machines.

Equipment List And Configuration for 10 TPH Compound Fertilizer Line

10 T/H Compound Fertilizer Powder & Granule Production Line

| Image | Name | Capaciteit | Stroom | Quantity |

| Powder Production Stage | ||||

|

Dynamtic Batching Machine | 10 e | 4.4 kW | 6 Bins |

|

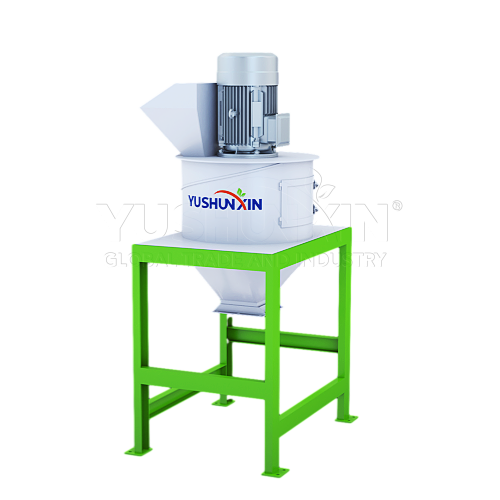

SXFLF-1000 Vertical Crusher | 8-15 e | 37 kW | 1 Set |

|

SXSJ-1050 Double Shaft Mixer | 10 e | 22 kW | 1 Set |

|

SXPJ-3000 Three-way Feeder | 8-12 e | 15 kW | 1 Set |

|

1515 Finished Product Bin | 1 Set | ||

|

B600-6/7/9/11/13m Conveyor | 5.5 kW | 5 Sets | |

|

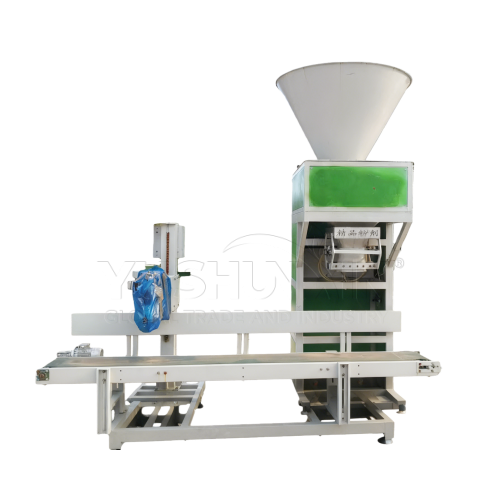

Powder Packing Scale | 10 e | 2.2 kW | 1 Set |

| Granulation Stage | ||||

|

SXZGZ-1870 Drum Granulator | 5-8 e | 15 kW | 1 Set |

|

SXHG-2020 Rotary Dryer | 8-15 e | 37 kW | 1 Set |

|

SXLQ-1818 Rotary Cooler | 7-12 e | 22 kW | 1 Set |

|

SXGS-1870 Rotary Screener | 10-15 e | 7.5 kW | 1 Set |

|

SXLTF-600 Chain Crusher | 2-5 e | 15 kW | 1 Set |

|

Coating Pot | 2.2 kW | 1 Set | |

|

SXBM-1560 Coating Machine | 15 kW | 1 Set | |

|

1515 Finished Product Bin | 1 Set | ||

|

Bucket Granule Packing Scale | 10 e | 2.2 kW | 1 Set |

|

SXFJ-8/10C Air Fan | 31237-43722 m³/u | 30 kW | 2 Sets |

|

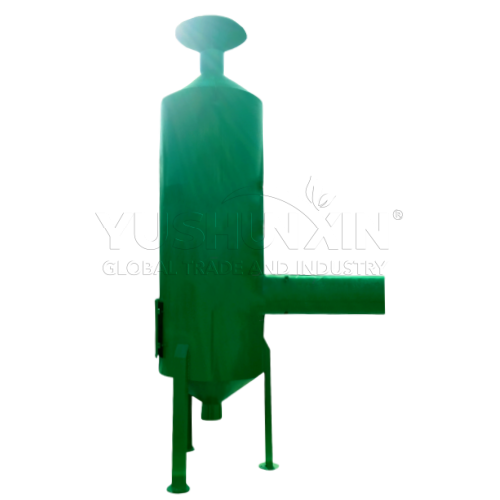

SXXF-1800 Cyclone Dust Collector | 2 Sets | ||

|

Water Curtain Dust Remover | 40m³ | 2.2 kW | 2 Sets |

|

Hot Stove | 1 Set | ||

|

B600-6/7/8/9/12/13m Conveyor | 5.5 kW | 8 Sets | |

Single 10 T/H NPK Fertilizer Wet Granulation Line

| Image | Name | Capaciteit | Stroom | Quantity |

|

SXWL-2040 Feeding Machine | 10 e | 6.75 kW | 1 Set |

|

SXSJ-1050 Double Shaft Mixer | 10 e | 22 kW | 1 Set |

|

SXZGZ-2080 Drum Granulator (SXYZ-3600 Disc Granulator) |

8-15 e (4-6 e) |

15 kW (18.5 kW) |

1 Set (2 Sets) |

|

SXHG-2020 Drum Dryer | 8-15 e | 37 kW | 1 Set |

|

SXLQ-1818 Drum Cooler | 7-12 e | 22 kW | 1 Set |

|

SXGS-1870 Rotary Screener | 10-15 e | 7.5 kW | 1 Set |

|

SXLTF-600 Chain Crusher | 2-5 e | 15 kW | 1 Set |

|

1515 Finished Product Bin | 1 Set | ||

|

Korrelverpakkingsweegschaal | 10 e | 2.2 kW | 1 Set |

|

SXFJ-8/10C Air Fan | 31237-43722 m³/u | 30 kW | 2 Sets |

|

SXXF-1800 Cyclone Dust Collector | 2 Sets | ||

|

Hot Stove | 1 Set | ||

|

B600-7/9/10/12/13m Conveyor | 5.5 kW | 8 Sets |

Comprehensive After‑Sales and Technical Support for 10 TPH Granulatielijn voor samengestelde meststoffen

The 10 TPH compound fertilizer granulation line delivers balanced capacity, flexible configuration, and stable wet granulation performance. Investors gain efficient NPK granule production, optimized energy use, and long‑term project value. Contact us for a detailed quotation and customized layout for your 10 t/h npk fertilizer granulation plant.

Ontvang nu een gratis offerte!