As a professional fertilizer equipment manufacturer, our company provides efficient and customized powder fertilizer production solutions. Each powder NPK fertilizer production system has compact structure and is cost-effective. Compared with granular fertilizer products, the NPK fertilizers powder production line offers lower energy consumption and simpler operation. Therefore, the demand for many new fertilizer manufacturers and small fertilizer plants to choose our NPK fertilizer powder production lines continues to grow.

Why Choose Our NPK Fertilizer Powder Manufacturing Line?

As a result, this powdery NPK fertilizers production system offers both high automation and strong adaptability. For agricultural enterprises or compound fertilizer factories, it becomes an ideal choice for fast setup, stable operation, and future project expansion.

4 Main Equipment in NPK Powder Fertilizer Production Line

UN complete NPK powder fertilizer manufacturing process includes several core machines. Each unit cooperates to maintain high nutrient uniformity and stable product quality.

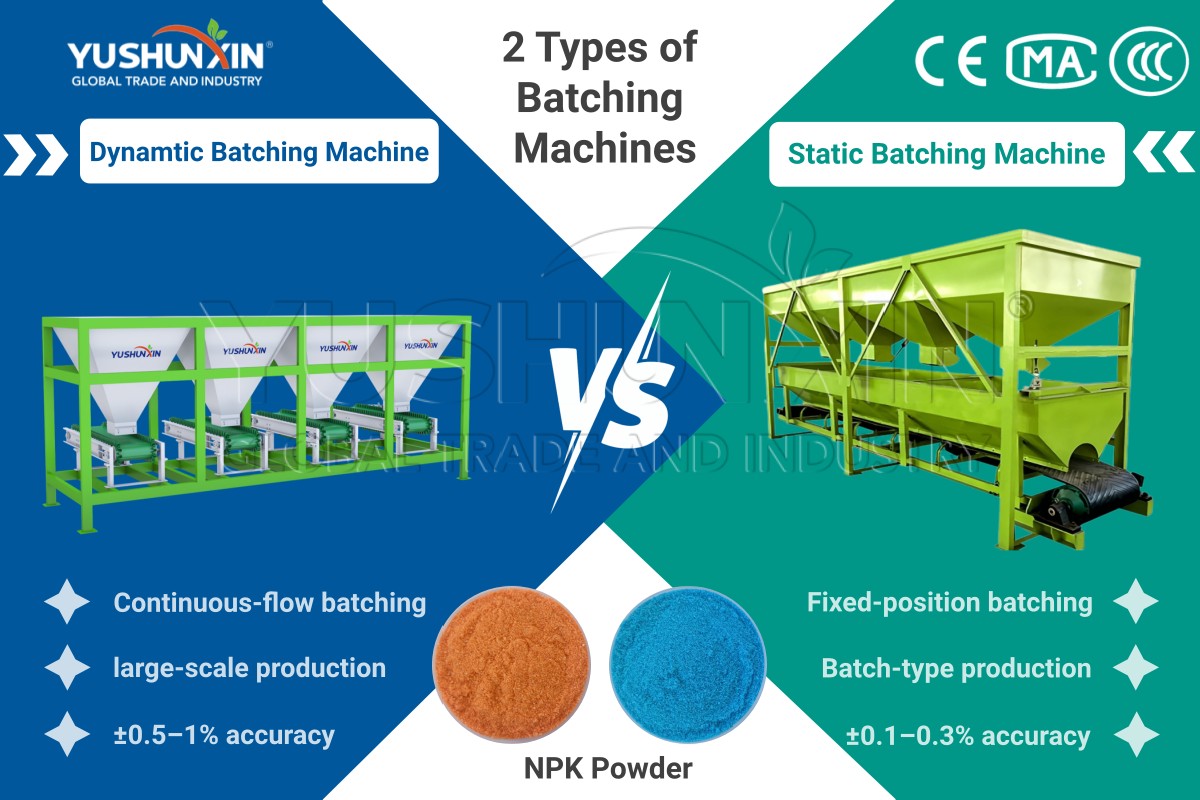

The batching system controls raw material proportions precisely for NPK fertilizer powder manufacturing. Our automatic batching equipment supports both static and dynamic weighing programs with PLC control system, ensuring accurate proportioning like urea, ammonium phosphate, potassium chloride. Ademas di, it allows operators to add additives such as micronutrients, conditioners, or stabilizers. According to your capacity, we suggest you buying two to four hoppers. Furthermore, you’d better choose belt or loader type feeder for smooth material feeding and stable flow.

In the NPK fertilizer production process, the crushing machine handles materials like urea, ammonium phosphate, and potassium chloride. For example, the urea crusher grinds urea granules to 0.5-2 mm; the cage crusher offers a high grinding particle size and large output for brittle NPK fertilizers with ≤1mm size; and the chain crusher can shred slightly damp or lumpy compound materials to a particle size of ≤3mm. In addition, you can choose powder screening equipment improves NPK powder product uniformity by removing oversized particles.

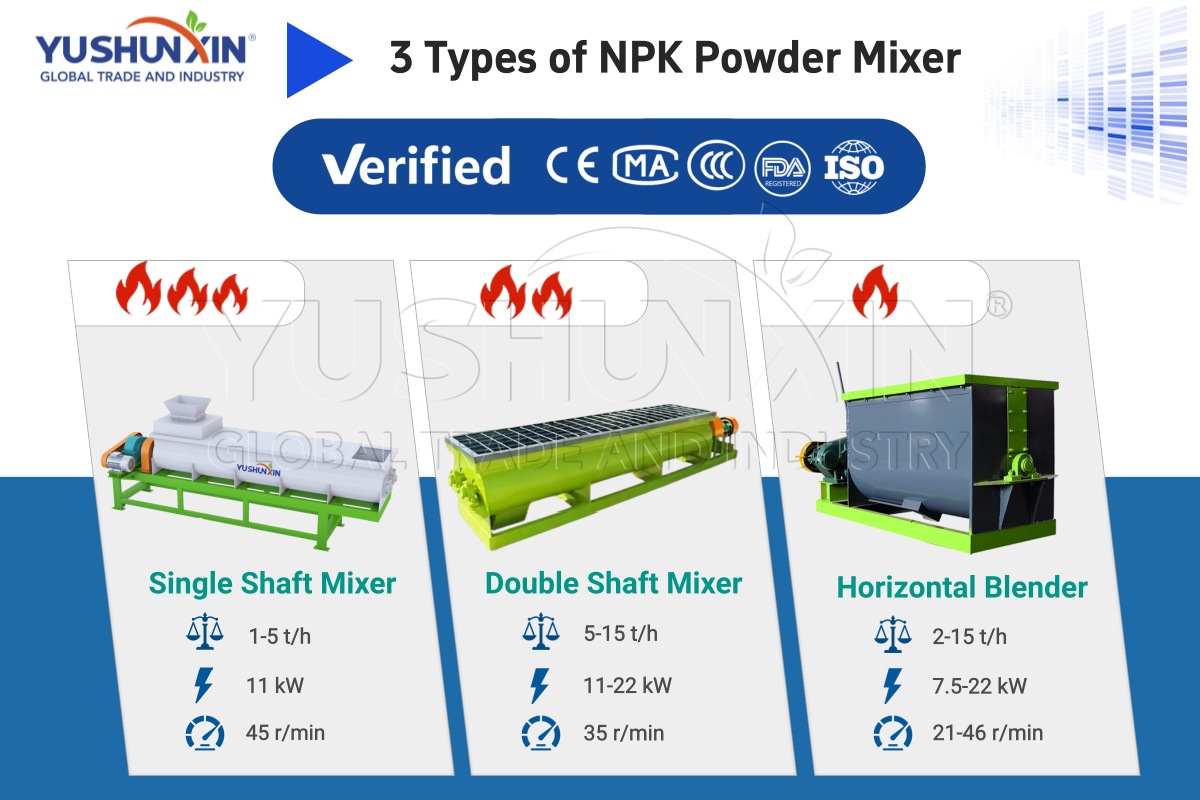

Indeed, mixing plays a central role in NPK fertilizer preparation. Our plant provides 3 types of NPK fertilizer mixing machines. For instance, the single-shaft mixer handles 1-5 t/h at 11 kW and 45 róchi, while the double-shaft mixer operates 5-15 t/h with 11-22 kW and 35 róchi. Also, the horizontal blender supports 2-15 t/h and 7.5-22 kW at 21-46 róchi. Therefore, each mixer features short mixing time, high homogeneity, and low energy use. You can select one according to material characteristics and required efficiency.

The NPK fertilizer powder packing machine handles25 krg and 50 krg bags with precise filling, weighing and sewing. Meanwhile, the conveyor system transfers finished NPK powder to the packing area smoothly. In addition, the NPK fertilizer powder production line equips a bag type dust collector, maintain a clean working environment. Ta p'esei, the overall design reduces manual labor and enhances automation, safety, environmental protection, and packaging accuracy.

A complete NPK powder fertilizer manufacturing process includes several core machines. Each unit cooperates to maintain high nutrient uniformity and stable product quality.

5 Steps of NPK Powder Fertilizer Production Process Flow

The entire NPK fertilizer powder manufacturing process follows five key steps.

Each step in the NPK fertilizer powder production system improves product quality. And production capacity ranges from 1 pa 20 tons per hour. Ademas di, the NPK fertilizer powder preparation technology ensures low energy use and high-quality output. Then, the final fine NPK fertilizer powder ready for farm application or secondary granulation. Also, the standard packaging method meets most international standards for fertilizer markets.

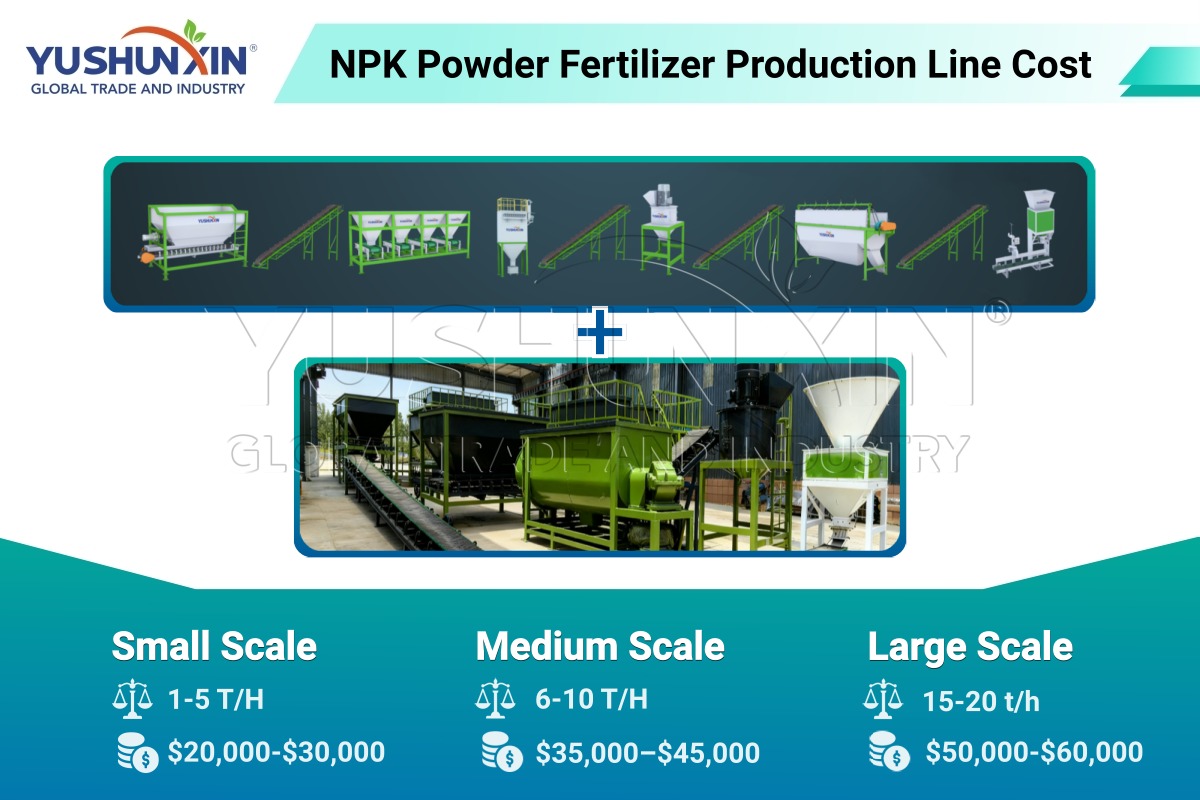

How Much Does An NPK Powder Fertilizer Production Line Cost?

The cost of an NPK fertilizer powder production plant depends on equipment configuration, capacity, and automation level.

Then, our company provides complete turnkey services for NPK fertilizer manufacturing program, including design, manufacturing, shipping, installation, and training. The delivery options include FOB or CIF according to your region. Normally, one to two 40-foot containers can ship a full compound fertilizer powder production line. And we support global delivery to Africa, the Middle East, Eastern Europe, and the Americas. By cooperating with our technical team, you can optimize cost-performance and receive a full NPK fertilizer powder plant ready for immediate operation.

In conclusion, the NPK fertilizers powder production line combines economic efficiency, flexible configuration, and strong market adaptability. Our company offers customized NPK fertilizer powder production solutions for different capacities and raw materials. Contact our technical team today to get a detailed quotation and production plan for your compound fertilizer manufacturing project.

Haña Preta Gratis Awor!