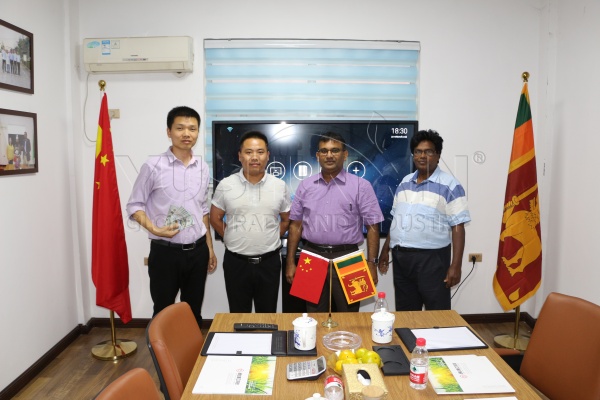

On August 20th, 2023, we received an inquiry from Mr. Sunil, a representative in the fertilizer production industry from Sri Lanka. Moreover, Sunil’s company was searching for a fertilizer mixing plant with a capacity of 2-3 tons per hour. In particular, he requested several types of equipment: a ribbon type mixing machine, disc granulator, rotary dryer, cooler, screening machine, and packing machine. Additionally, he also asked for the best CIF Colombo price, layout drawings and installation costs for our engineers.

Granular Manufacturing Requirements of Sri Lankan Customer

A Cost-effective NPK Fertilizer Granulation Plan We Offer for Sri Lankan Customer!

Fertilizer Mixing Machine for Efficient Blending

At the beginning, Sunil asked if we have ribbon type mixer. Firstly, we recommended the most suitable mixer for NPK blending plant – BB fertilizer mixer. However, its capacity is beyond his actual production situation. So we purposed SXWJ-7015, at $1800USD, a horizontal mixer meeting his output requirements. Compared to ribbon mixer, it can fully mix NPK compounds, ensuring even distribution of the components in the NPK fertilizer. Also, it has good adaptability to materials of different particle size and density, and can handle a variety of raw materials. Most importantly, our equipment has spiral blades, which have a certain crushing function in the face of massive phosphate fertilizer and kaolin.

Wet Granulator for NPK Fertilizer Powder Aggregation

A wet granulator effectively aggregates NPK fertilizer powder. So, the disc granulator efficiently processes raw materials such as graphite, apatite, phosphate, kaolinite, ball clay, and brick clay. Additionally, we can install a water-spray device to enhance granulation effect. Whatever, Sunil can get 2-3 tons of round compound fertilizer pellets pre hour with the diameter of 3-4mm. Above all, we can also design a single dust-proof chamber to maintain a cleaner operational environment and prevent dust spill. In short, the 2-3t/h pan granulator costs $3,825, providing excellent value for its capabilities. Besides, adding a dust chamber costs an additional $2,000. Consequently, the disc granulator, with optional enhancements, is an excellent choice for NPK fertilizer powder pelletizing.

What Auxiliary Equipment Does The Sri Lankan Customer Choose?

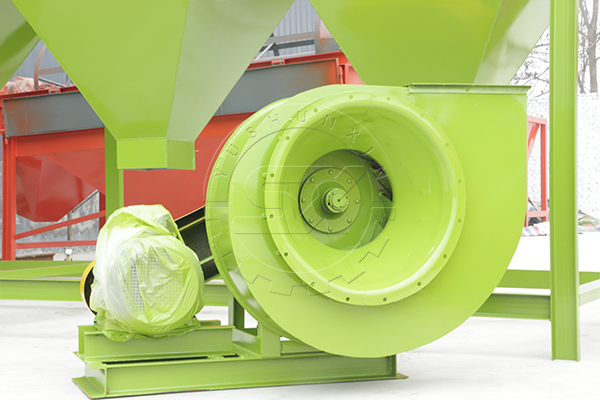

Keeping <10% Moisture in NPK Granules By YSX Machines

Maintaining moisture levels below 10% in NPK granules is crucial for quality and longevity. Firstly, we recommended a rotary drum dryer and a cooler for this Sri Lankan customer. Because the former process of NPK granules production uses wet granulation. At this time, these particles contain approximately 20% moisture, which makes storage and transportation challenging. A dryer effectively reduces the moisture content to 2-5%, ensuring the granules packing and selling. Additionally, a rotary cooler prevents the granules from cracking by providing a lower temperature.

In terms of cost, a drum dryer with a capacity of 2-3 tons per hour costs approximately $10,125. For the same capacity, he needed a slightly smaller cooler model, around $7,800. In general, our factory also supply a 6C induced draft fan and a hot air furnace to enhance the drying and cooling processes. Given the availability of agricultural waste in the local area, we recommend a biomass pellet burner. This burner is both eco-friendly and cost-effective, promoting sustainable energy use. Moreover, the air fan costs approximately $2,500, while the hot air furnace is priced at $3,700.

NPK Granule Screening Machine & Packing Scale for Sale

Producing NPK granules requires efficient equipment. A rotary screening machine and a granule packaging scale are highly necessary. These machines offer significant benefits. For example, the rotary screening machine ensures precise particle size separation, enhancing product quality. Also, the granule packaging scale guarantees accurate and speedy packaging, reducing labor costs. Thus, a screening machine with a capacity of 2-3 tons per hour costs about $1,670. Meanwhile, a granule packaging scale with the same capacity costs about $4,000. Investing in these machines optimizes the production process and increases overall efficiency. Therefore, they represent valuable additions to any NPK granule manufacturing plant setup.

Transportation Scheme for NPK Fertilizer Granulation Line to Colombo

Our dedication to quality and service ensures that our clients receive the best equipment and support. For further details on our products and services, visit our website or contact our sales team. We look forward to helping you achieve your production goals with our reliable and efficient equipment solutions.