플랫 다이 펠렛 밀

The choicest Granulator — Columnar Organic Fertilizer Flat Die Pellet Mill

Our company has currently developed 평평한 다이 세포터, which is one of the main organic fertilizer production equipment. 게다가, we design and upgrade it on the basis of the traditional organic fertilizer granulators, overcoming the problems of organic fertilizer like looseness and difficulty in granulation.

- The machine has simple mechanism and reasonable design, and the granules are easy to dry with low water content.

- 게다가, the granular materials processed by this machine have smooth surface, moderate hardness, and can well maintain the internal nutrients during processing.

We offer a number of models with various types that are appropriate production equipment for small and medium scale fertilizer manufacturing plants. Compared with traditional devices, the flat die pellet mill has great advantages and is considered to be a more efficient way in fertilizer production.

The flat die pelletizer produces columnar pellets without drying or crushing process, which saves a lot of energy. 게다가, it will undoubtedly be the best choice for your organic fertilizer granule production!

Obvious Practical Applications of Flat Die Pellet Mill

평평한 다이 세포터 is ideal for coarse fiber granulation such as wood chips, 빨대, 쌀 껍질, 면 줄기, 잡초 및 다른 종류의 농업 폐기물, 국내 쓰레기뿐만 아니라, 폐기물 플라스틱, 산업 폐기물. 게다가, it is useful for granulation and briquetting of materials with low adhesion rate and difficult to shape, and it can also be applied to low temperature granulation of bio-fertilizer, organic fertilizer and compound fertilizer.

평평한 다이 세포터 is mainly used for pellet processing of (biological) organic fertilizer and breeding industry, and it can also be used as livestock feed. 비슷하게, it can be used as biomass fuel for boilers, gasifiers, gas stations, and biomass power plants.

Production Procedure by Flat Die Pellet Mill

- The complete granulation line with 평평한 다이 세포터 includes the following equipment: crusher, conveying machine, mixer, 평평한 다이 세포터, dryer, cooler, screening machine, storage bin and packaging machine.

- 평평한 다이 세포터‘s function is to granulate from organic fertilizer after composting.

1. Differing from the usual method, it eliminates the drying and crushing process of raw materials before granulation, and makes direct batching for processing columnar granules.

2. After the granules form, you can omit the drying and cooling steps, or choose to carry on the finish machining.

- The simplest process flow: conveying → compression molding → storing → packing.

메모:

- Raw materials like livestock manure with high water content need to be dried before granulation to reduce the moisture.

- Composted materials generally do not need to be finely crushed, while wood chips with suitable moisture can be directly granulated.

- To avoid damage to the roller surface, raw materials with large volume or density must be crushed in advance.

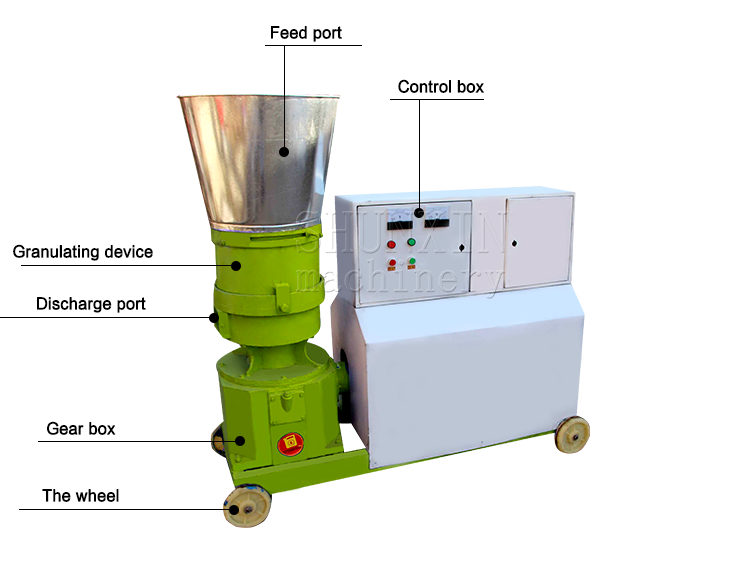

Structure Overview

The main structure of flat die pellet mill consists of feeding and discharging system, granulation system, transmission system and control system.

그중, the flat die 그리고 extrusion rollers are this kind granulators’ main components, whose service life and working condition will directly affect the granulating effect, service life and production efficiency of the entire devices.

How Does A Flat Die Pellet Mill Work?

- 첫 번째, the flat die granulator is based on the mechanical circular motion and powered by an electric motor.

- 마찰의 행동하에, the extrusion rollers rotate themselves and the temperature increases between them and materials, 고온으로 인해 재료가 녹게됩니다.

- 일할 때, the flat die granulator uses extrusion rollers and molds to extrude materials with the shape of strips through the small holes of molds.

- 마지막으로, 출구에서 배출하는 동안, the cutting knives cut these strips to a certain length for finished products.

Why Is The Flat Die Granulator Popular In The Market?

Pellet Mill Flat Die Specifications

|

모델 |

용량 (t/h) | 힘 (KW) | Pellet Diameter (mm) |

| SXPM-400 |

1-1.5 |

30 |

2-10 |

|

SXPM-500 |

1.5-2 |

37 |

|

|

SXPM-600 |

2-2.5 |

45 |

지금 무료 견적을 받으십시오!