nuestra empresa produces volteador de compost tipo ranura for sale as organic fertilizer production machine. It has the advantages of reasonable structure, high efficiency, low energy consumption, high degree of automation, easy operation, low cost, and wide range of applications. De este modo, it becomes the model which customers warmly welcome.

Materias primas & Aplicaciones

Groove tipo compost máquina is usually also known as rail type compost turner, trough tipo composting máquina and so on. And it can be used for the fermentation organic wastes such as livestock and poultry manure, lodos y basura, filter sludge in the sugar mill, dregs, cake and meal, straw and sawdust, etc..

It is widely used in organic fertilizer factory, compound fertilizer factory, sludge and garbage factory, horticultural farm and agaricus bisporus plant, etc.. for the operation of fermentation, decomposition and moisture removal.

the composting span can be between 3-30 meters, and the turning depth can be between 0.8-1.8 meters. Además, we have various specifications of double-groove type and half-groove type to meet the different needs of customers.

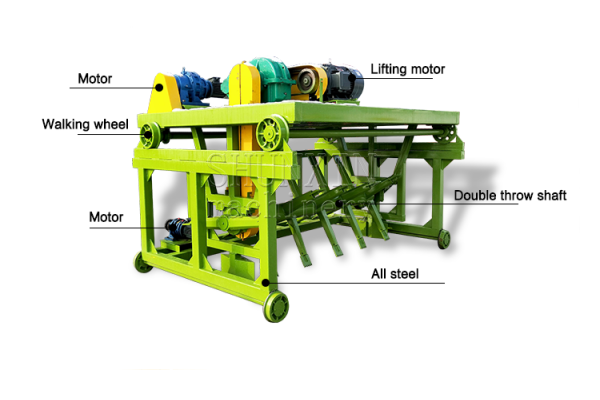

Equipment Construction of Groove Type Compost Turner

Trough type compost turning machine consist of the transmission device, the lifting device, the walking device, the composting device, the transfer car and other main components.

How Does A Groove Type Compost Machine Work?

The electric motor directly transmits the power to the cyclonic reducer through the sprockets, and then to the rotary cylinder. Además, the stirring paddles on the cylinder are distributed in a spiral shape. And the paddles turn and stir the materials in the fermentation grooves and push them forward 0.2-1metro far away. Por eso, this plays the effect of fast composting speed and even stirring, so as to achieve the full contact between the materials and the air, and finally make the materials have a good fermentation effect.

Main Features of Groove Type Compost Turner

- 1

El groove type compost tornero is suitable for aerobic fermentation. Además, it cooperate with the transfer car to realize the function of one machine with multiple troughs.

- 2

This compost equipment can achieve both continuous and batch discharging, with high efficiency, smooth operation, and durability.

- 3

The control cabinet can centralized regulate this machine to realize manual or automatic control function.

- 4

Equipped with soft starter, the trough type composter has low impact load when starting.

- 5

The rotary blades are sturdy and durable, and have the function of breaking and mixing the materials.

- 6

The groove type compost turner has limit switch, and plays the role of limit and safety.

Sobre todo, nuestro volteador de compost tipo ranura is secure and high-quality. Además, we have sufficient special after-sales personnel. If your equipment face any problems, one year warranty for your decision!