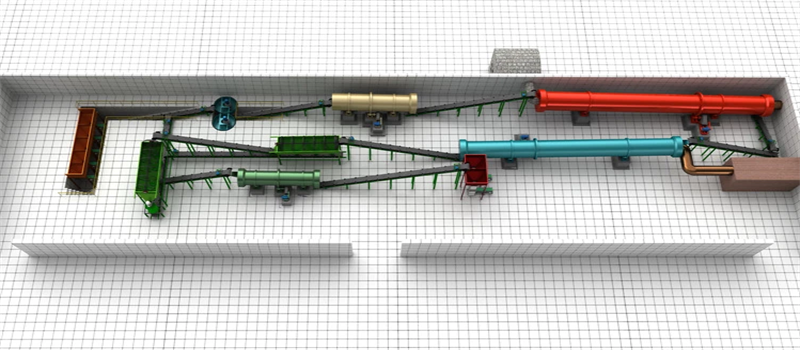

Dây chuyền sản xuất phân bón hỗn hợp

Our company offers the compound fertilizer production equipment with compact layout, scientific and reasonable design, and advanced technology. Hơn nữa, they have advantages of energy saving and consumption reduction, no environmental pollution, stable operation, reliable operation and convenient maintenance.

- Its wide adaptability of raw materials make it applied frequently in compound fertilizer, pharmaceutical, hóa chất, feed and other industrial granulation, with a high granulation rate.

- Basic raw materials of compound fertilizer production need to be crushed to a certain fineness, chẳng hạn như ammonium nitrate, urê, ammonium chloride, calcium nitrate, potassium chloride, potassium sulfate, vân vân.

Compound Fertilizer Production Process

Compound fertilizer process contains raw material batching, mixing, granulation, sấy khô, làm mát, screening, coating, packing parts.

What Is The Equipment Needed for Compound Fertilizer Production Line?

1. Batching System

Batching system mainly consists of feeding system, weighing device, stock bin and conveyor belt. Ví dụ, static batching machine has higher precision, better stability and easier measurement compared with dynamic batching machine.

Dynamic batching machine is suitable for continuous proportioning which is adaptive for large scale industrial production. It has higher working efficiency and degree of automation than static batching machine.

2. Mobile Belt Conveyor

Compared with the ordinary băng tải đai, it increases the mobile device and lifting device, which makes conveying capacity increase. Kể từ đây, we advise you can equip with a loader to change the appropriate place for loading and unloading materials.

3. Horizontal Mixer

Horizontal mixer is a generic mixing machine. It widely occurs in chemical industry, pharmaceutic industry, food processing plant, architectural material industry and other fields.

4. Rotary Drum Granulator

Rotary drum granulator is a molding machine that can make material to a specific shape. It is also one of the key equipment in compound fertilizer industry. Hơn thế nữa, this machine has good appearance quality, corrosion and wear resistance, tiêu thụ năng lượng thấp, long service life, simple operation and maintenance, vân vân.

5. Rotary Screening Machine

The rotary screening machine is commonly used in compound fertilizer production, which is mainly used for the separation of finished products and returned materials, but also achieves the classification of granules. Bên cạnh đó, the machine has easy maintenance, simple structure, easy and smooth operation, which is the ideal equipment in compound fertilizer production.

6. Rotary Coating Machine

Rotary coating machine consists of screw conveyor, rotary cylinder, oil pump, động cơ, reducer, and gears. It can effectively prevent the agglomeration of compound fertilizer. The inner cylinder consists of polypropylene or stainless steel with good corrosion resistance.

7. Packing Machine

The automatic quantitative packaging machine, which includes single bucket packaging scale and double one, is a mechanical device for quantitative weighing and packaging of granule and powder shape of bulk materials.

Why Choose Our Compound Fertilizer Production Line?

Nhận báo giá miễn phí ngay bây giờ!