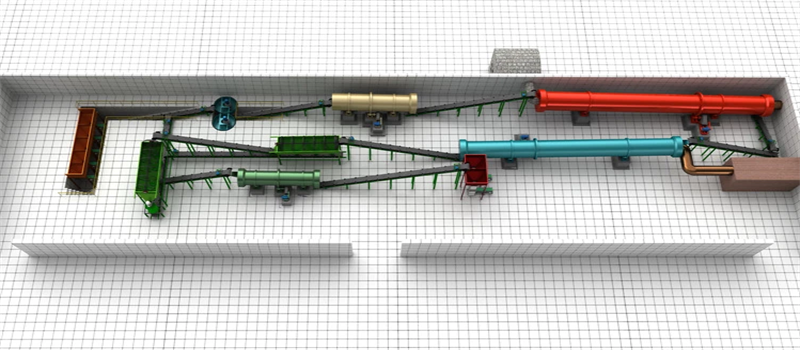

Línea de producción de fertilizantes compuestos

Our company offers the compound fertilizer production equipment with compact layout, diseño científico y razonable, y tecnología avanzada. Además, they have advantages of energy saving and consumption reduction, no environmental pollution, operación estable, operación confiable y mantenimiento conveniente.

- Its wide adaptability of raw materials make it applied frequently in compound fertilizer, pharmaceutical, químico, piensos y otros tipos de granulación industrial, con una alta tasa de granulación.

- Basic raw materials of compound fertilizer production need to be crushed to a certain fineness, como nitrato de amonio, urea, ammonium chloride, calcium nitrate, cloruro de potasio, sulfato de potasio, etc..

Proceso de producción de fertilizantes compuestos

Compound fertilizer process contains raw material batching, mezclando, granulación, el secado, enfriamiento, cribado, revestimiento, packing parts.

What Is The Equipment Needed for Compound Fertilizer Production Line?

1. Batching System

Batching system mainly consists of feeding system, weighing device, stock bin and conveyor belt. Por ejemplo, máquina dosificadora estática has higher precision, better stability and easier measurement compared with dynamic batching machine.

Dynamic batching machine is suitable for continuous proportioning which is adaptive for large scale industrial production. It has higher working efficiency and degree of automation than máquina dosificadora estática.

2. Mobile Belt Conveyor

Compared with the ordinary cinta transportadora, it increases the mobile device and lifting device, which makes conveying capacity increase. Por eso, we advise you can equip with a loader to change the appropriate place for loading and unloading materials.

3. Mezclador Horizontal

Mezclador horizontal is a generic mixing machine. It widely occurs in chemical industry, pharmaceutic industry, food processing plant, architectural material industry and other fields.

4. Rotary Drum Granulator

Rotary drum granulator is a molding machine that can make material to a specific shape. It is also one of the key equipment in compound fertilizer industry. Además, this machine has good appearance quality, corrosion and wear resistance, bajo consumo de energía, larga vida útil, simple operation and maintenance, etc..

5. Máquina de cribado rotativa

La máquina de cribado rotativa is commonly used in compound fertilizer production, which is mainly used for the separation of finished products and returned materials, but also achieves the classification of granules. Además, the machine has easy maintenance, simple structure, easy and smooth operation, which is the ideal equipment in compound fertilizer production.

6. Rotary Coating Machine

Rotary coating machine consists of screw conveyor, rotary cylinder, oil pump, motor, reductor, and gears. It can effectively prevent the agglomeration of compound fertilizer. The inner cylinder consists of polypropylene or stainless steel with good corrosion resistance.

7. Packing Machine

La máquina automática de envasado cuantitativo., which includes single bucket packaging scale and double one, is a mechanical device for quantitative weighing and packaging of granule and powder shape of bulk materials.

Why Choose Our Compound Fertilizer Production Line?

Obtenga una cotización gratuita ahora!