100,000 T/Y NPK Compound Fertilizer Plant Cost in Algeria

On June 22, 2024, a professional inquiry arrived from an Algerian petrochemical enterprise based in Algiers, in Algeria. Mr. Karim, the project director, plans to establish an NPK compound fertilizer factory with the annual capacity of 100,000 tons using nitrogen, phosphorus and potassium as raw materials. Because Algeria's warm and dry climate, limited domestic fertilizer output, and growing agricultural demand encouraged the company to invest in technologie de granulation d’engrais NPK. Thus, this transition allows the company to enhance petrochemical by-products and to penetrate national and export fertilizer markets. Taking into account local environmental policies, he set high expectations for energy efficiency, automation, and dust control. Additionally, he wished us offering NPK granulation line specifications, detailed flow charts, layout planning, quotations and after-sales. After receiving this inquiry, our team immediately engaged in follow -up discussions to provide a customizable NPK compound fertilizer production solution.

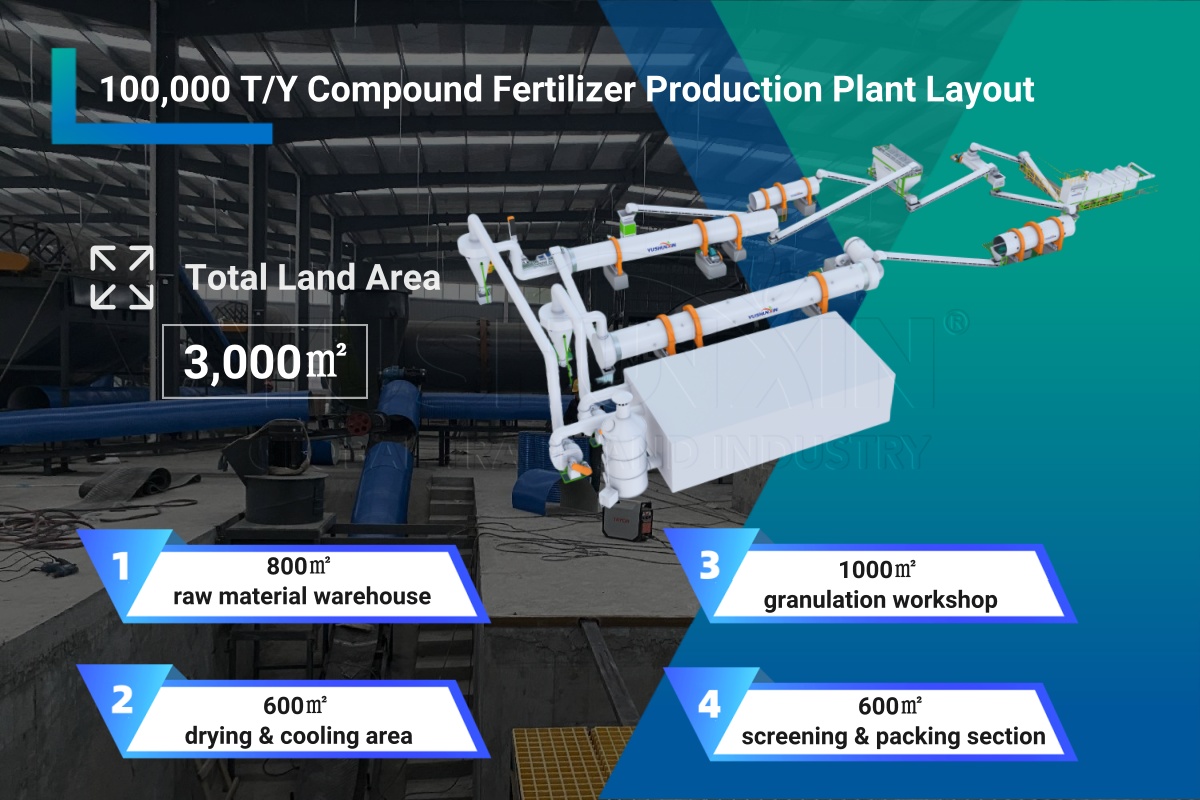

How to plan the layout of a 100,000 T/Y Compound fertilizer production plant layout?

Firstly, Mr. Karim informed us that an existing facility of 5,000㎡ was available for fertilizer equipment installation. And, he requested a diagramme du processus de production d’engrais composé and a facility layout plan showing equipment arrangement and required space. Considering the annual production capacity of 100,000 tons of compound fertilizer, we recommended a 20 TPH rotary drum granulation line and provided the corresponding drawings. Actually, the NPK compound fertilizer pellet manufacturing process that we have proposed includes raw materials crushing, automatic batching, mixing, granulating, drying, cooling, screening, coating and packaging. Additionally, the fertilizer equipment layout is compact, adopting an U-shaped material flow design to reduce NPK handling distances. Additionally, the complete 20 t/h NPK compound fertilizer production line occupies about 3,000 square meters, including 800㎡ raw material warehouse, 1,000㎡ granulation workshop, 600㎡ drying & cooling area and 600㎡ screening & packaging section.

How much does it cost to build a 100,000 T/y Granular compound fertilizer plant ?

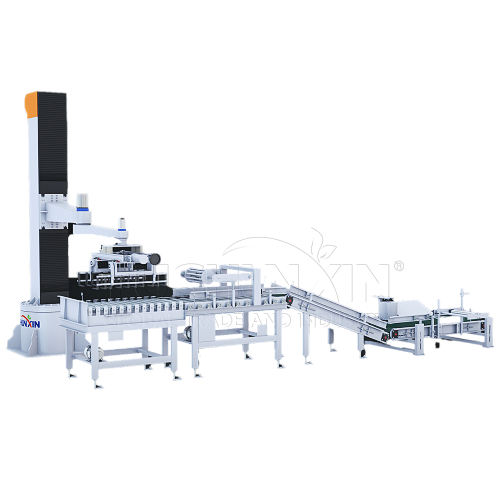

After multiple discussions, the customer, Mr. Karim, decided to visit our factory on August 13, 2024. During the visit, we led a tour of our fertilizer equipment production workshop, presented factory operations and provided relevant technical documents. And, we can offer a 15 % discount about 20 t/h NPK fertilizer manufacturing plant cost, including all equipment and services. Furthermore, The basic compound fertilizer equipment list included a crusher, a mixer, drum granulator, dryers, cooler, conveyors, packaging machines, etc. The total price, after the discount, was from 403,482 USD (about 53,4 million Algerian Dinar). Consequently, Mr. Karim accepted payment by L/C and paid a deposit of $161,392.80 on August 20. Then, we have completed the manufacture of the 20 t/h compound fertilizer granule production equipment within 15 working days. And on 25 september, he settled 60 % balance before shipping.

Core equipment list for 20 T/H NPK fertilizer production line

| Name | Model | Capacity | Power | Quantity | |

|

Double-chain Crusher | SXLTF-800Ⅱ | 10-15 T/H | 18.5 kw*2 | 1 Set |

|

Dynamic Batching Machine | SXPL-1815 | / | 4.4 kw*4 | 4 Bins |

|

Double Shaft Mixer | SXSJ-1050 | / | 22 kw | 1 Set |

|

Rotary Drum Granulator | SXZGZ-2210 | 15-20 T/H | 25 kw | 1 Set |

|

Rotary Dryer | SXHG-2222 | 8-16 T/H | 37 kw*2 | 2 Sets |

|

Drum Cooler | SXLQ-2020 | 8-15 T/H | 37 kw | 1 Set |

|

Cyclone Dust Collector | SXXF-1800 | / | 0 | 2 Sets |

|

Air Fan | SXFJ-10C | / | 30 kw*2 | 2 Sets |

|

Water Curtain Dust Remover | SXSM-1500 | / | 2.2 kw*2 | 2 Sets |

|

Natural Gas Burner | / | / | 20 kw*2 | 2 Sets |

|

Hot Stove | / | / | 0 | 2 Sets |

|

Coating Machine | SXBM-1870 | / | 15 kw | 1 Sets |

|

Twin-bucket Packing Machine | / | 25-50kgs/bag | 2.2 kw | 1 Sets |

|

Robot Palletizer | TY-LZ-500 | 300~400 bags/h | 11.25 kw | 1 Sets |

|

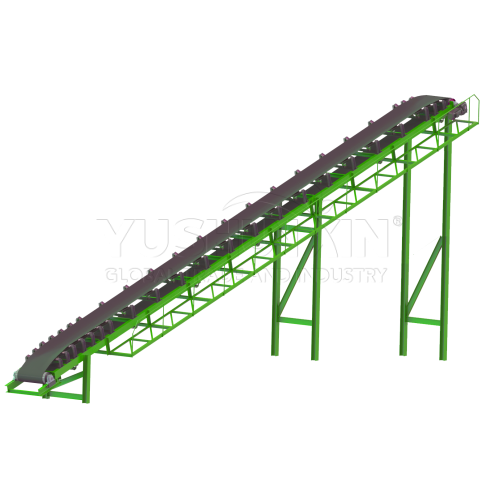

Belt Conveyor | 500m, 600m, 800m | / | 5.5 kw | 13 Sets |

| Total Power | 416.95 kW | ||||

| Total Price | 474,685 USD 403,482 USD (53.419,214 DZD) | ||||

How about the transportation and installation service of the 20 TPH Compound Fertilizer Production Machines?

What feedback did we receive from 20 T/H Algerian NPK Fertilizer Factory?

On November 20, 2024, the 20 t/h compound fertilizer plant entered formal operation. Mr. Karim, the project director, shared his feedback:

"Yushunxin's team demonstrated professionalism throughout the NPK fertilizer manufacturing project design and execution. And, the equipment has arrived punctually, and installation and commissioning was efficient. The first batch of trial pellets complied with international standards for NPK fertilizers (N ≥ 15 %, P₂O₅ ≥ 15 %, K₂O ≥ 15 %). The actual capacity has reached 21.3 tonnes per hour and dust emissions were less than 15 mg/m³.”

100,000 T/Y NPK Compound Fertilizer Plant Cost in Algeria

We invite other customers to consult us for different fertilizer production solutions. Yushunxin provides comprehensive services in project work on the NPK fertilizer production, from planning and cost estimation to equipment supply and installation. Additionally, our company designs economic solutions for compound fertilizer manufacturing processes, granulation techniques and fertilizer production machinery. Currently, we have a branch in Algeria with Arabic and French-speaking sales team. If you are interested in NPK fertilizer granulation, you can directly visit our office for face-to-face discussions.