Trench type compost turner offers an efficient solution for managing large volumes of organic waste. These machines are widely used in fertilizer manufacturing due to their strong adaptability, low energy use, and excellent fermentation results. Understanding their structure, working process, and compostable materials helps oeganic fertilizer producers make smarter equipment investments.

Trench type compost turner offers an efficient solution for managing large volumes of organic waste. These machines are widely used in fertilizer manufacturing due to their strong adaptability, low energy use, and excellent fermentation results. Understanding their structure, working process, and compostable materials helps oeganic fertilizer producers make smarter equipment investments.

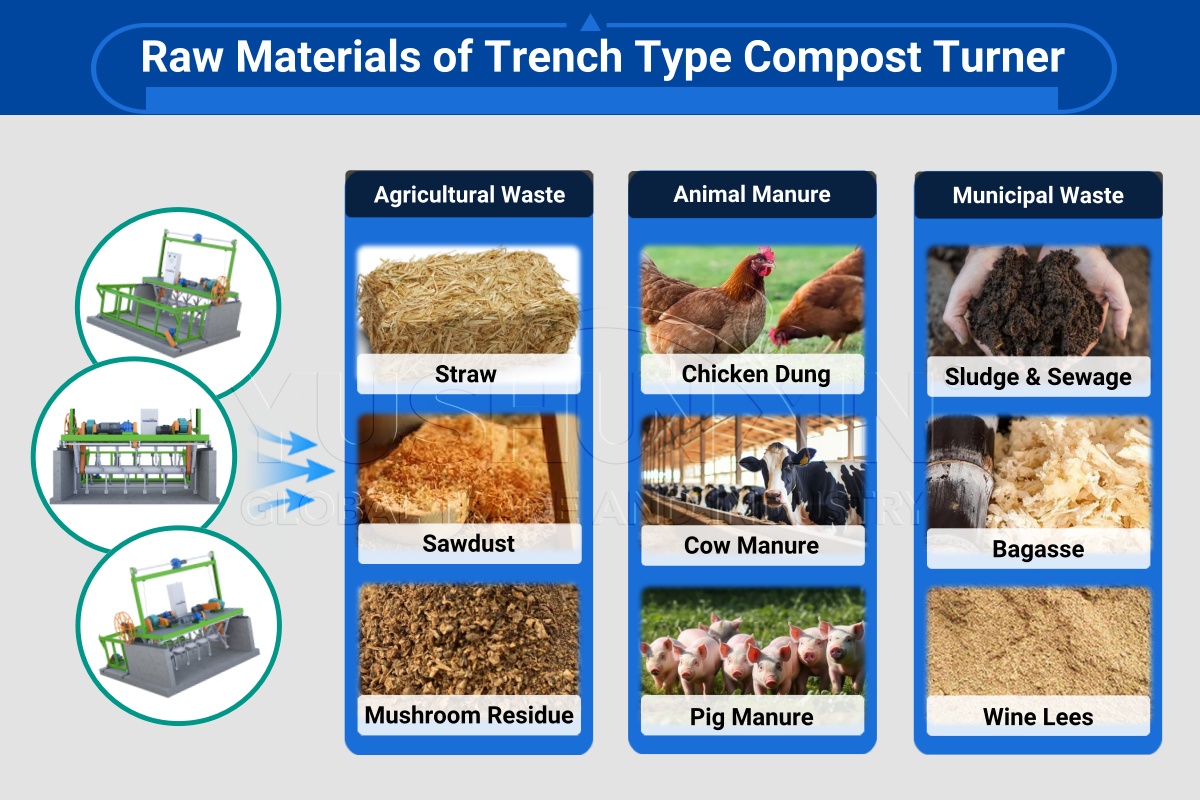

What Materials Can You Compost by Trench Type Compost Turner?

The trench type compost machines can decompose and ferment a wide range of organic waste. In practice, these materials include livestock manure, agricultural waste, municipal waste, industrial waste, and by-products from food processing, etc. Besides, this groove type composting technology accelerates the composting process and improves compost quality.

Specific Organic Compost Materials as Follows

As a result, groove type compost turner has wide applications in many fields. You can use it in organic fertilizer production plants, compost manufacturing facilities, sludge disposal sites, and garden areas. Therefore, our trench type composting machines meet your needs for efficient fermentation and moisture removal in compost production processes.

What Is The Structure of a Groove Type Compost Turner Machine?

Common groove type compost turner machine has three primary systems: the driving system, compost turning system, and moving mechanism. Each component is vital for efficient compost production. Additionally, electricity serves as the main power source.

Firstly, the driving system includes a motor, a reducer, sprocket wheels, bearings, and a spindle box. This system generates power for the entire machine, ensuring smooth operation of the composting equipment. It is essential for producing the energy needed in the organic compost process.

Secondly, the compost turning system has two parts: the lifting device and the composting device. The former includes a winding engine, coupling, transmission shaft, and bearings. Moreover, the latter contains sprocket wheels, paddle blades, a supporting frame, and a turning cylinder. These components work together to turn and aerate the compost effectively.

Finally, the moving mechanism consists of a motor, transmission gears, transmission shaft, and walking sprocket wheels. This mechanism enables the trench type compost turner to move along rails within the composting groove. It allows for consistent movement and efficient composting techniques.

Besides, understanding these components helps you choose the right groove type composting machine for your manufacturing process. Our company offers comprehensive composting machinery solutions for fertilizer production.

How to Turn Organic Waste into Compost by Trench Type Compost Turner?

Converting organic waste into compost is essential for sustainable agriculture. Also, groove type compost machines provide an efficient solution. In practice, the working principle of simple groove type compost turner has four steps.

4 Steps to Make Compost by Rail Composting

- 1

Firstly, you need to install tracks on the walls of long fermentation grooves. Then the rail type compost equipment can move back and forth along the track on the grooves.

- 2

Secondly, the motor transmits power directly to the reducer, and then to the turning cylinder by the sprocket wheels. Besides, the mixing paddle blades are in spiral distribution.

- 3

Meanwhile, as this compost turning machine walks forward, the rotating paddle blades turn, break, and throw the organic materials backward.

- 4

Additionally, you may use the groove compost turning machine in conjunction with a transitional machine to move to the next groove. Therefore, a single organic compost machine can service multiple grooves.

In conclusion, the trench type compost turner streamlines the composting process. It enables fertilizer manufacturers to turn organic waste into high-quality compost effectively.

What Is the Price of Groove Type Composting Machine?

Our factory offers four customizable models of groove type composting machines, with turning widths of 2.5m, 3m, 4m, and 5m. Additionally, the default turning depth is 80 cm. Besides, our prices range from $6,500 to $16,000, including the electric cabinet, cable reel, and displacement car. If you require additional mechanical or hydraulic systems for your composting process, an extra cost of $2,000 to $3,000 is needed.

Parameters Table of Rail Type Compost Machinery

| Model | Main Motor (kw) | Moving Motor (kw) | Lifting Motor (kw) | Turning Width (mm) | Turning Depth (mm) |

| SXCF-2500 | 15 | 1.5 | 0.75 | 2500 | 800 |

| SXCF-3000 | 18.5 | 1.5 | 0.75 | 3000 | 800 |

| SXCF-4000 | 15*2 | 1.5 | 0.75 | 4000 | 800 |

| SXCF-5000 | 18.5*2 | 1.5 | 0.75 | 5000 | 800 |

Why Choose Our Trench Type Compost Turner Machine for Your Organic Fertilizer Manufacturing Process?

Our trench type compost turner is the first choice for fertilizer manufacturers seeking efficient organic fertilizer fermentation solutions. Because it offers high output with low energy consumption, making your composting process more economical. Furthermore, our groove type composting machinery has a stable structure and a low failure rate. Thus, it ensures reliable operation in your organic fertilizer manufacturing process.

In a word, choosing our trench type compost turner machine equips your fertilizer manufacturing process with efficient, reliable, and cost-saving composting technology. By addressing your needs for high output, low energy consumption, and excellent fermentation effects, our equipment stands out as the optimal choice for your organic fertilizer production.

With proven efficiency and a solid structure, trench type compost turners are essential in modern composting systems. They help reduce costs, increase output, and improve compost quality—making them a smart choice for sustainable organic fertilizer production.

With proven efficiency and a solid structure, trench type compost turners are essential in modern composting systems. They help reduce costs, increase output, and improve compost quality—making them a smart choice for sustainable organic fertilizer production.

Get Free Quote Now!