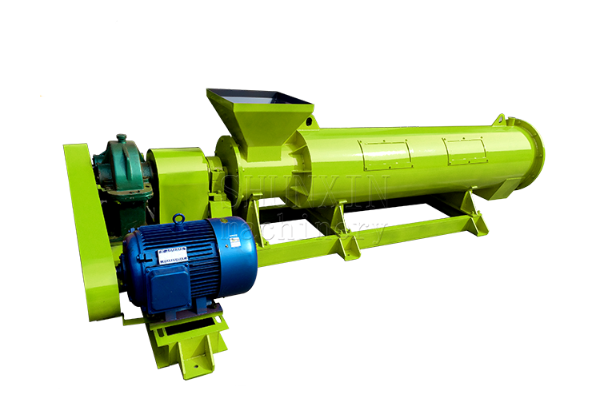

New Type Organic Fertilizer Granulator

Quality Organic Granular Fertilizer Manufacturing with Our Granulator!

Our newly invented organic fertilizer granulator, also known as churning granulator, is widely used for the granulation of various organic fertilizers. The majority of consumers chose as the optimal product because of the high pelletizing rate, smooth operation, robust and durable equipment, and long service life. Our factory can produce and build various specifications of new type organic fertilizer granulators according to the requirements of users.

This machine is suitable for granulating organic fertilizer directly after fermentation, eliminating the drying process and greatly reducing the cost. A lot of organic fertilizer companies currently favor our designed new type organic fertilizer granulators. New design, new production process, energy saving and environmental protection that deserve your trust!

Effective Use of Organic Matter — New Type Organic Fertilizer Granulator

This new organic fertilizer granulator is capable of granulating a wide range of organic materials, particularly light granule powder materials. It is helpful for coarse fiber materials to form spherical particles. The finer the basic particles of the powder material are, the fuller the ball shape and the better the pelletizing quality they will be. General criteria of the material granulation before the particle size should be less than 50 mesh is appropriate.

What Is Granulation Method for New Type Organic Fertilizer Granulator?

The main working method of new type organic fertilizer granulator manufacturer is polymeric wet granulation. By a certain amount of water or steam, the wet base fertilizer is reacted inside the cylinder. Under certain liquid conditions, the materials are squeezed together with the rotation of the barrel to form granules.

Then they use the mechanical stirring force of high speed rotation and the resulting aerodynamic force to make the fine powdery material continuously realize the process of mixing, granulation, spheroidization and densification in the machine, so as to achieve the purpose of granulation.

New Type Organic Fertilizer Granultor Features

Specification of Screw Press Dewatering Machine

|

Model |

TDJZ-60 | TDJZ-80 | TDJZ-100 | TDJZ-120 |

TDJZ-150 |

|

Installation Angle (。) |

2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 |

| Capacity (t/h) | 1-1.5 | 1.5-2.5 | 2-4 | 4-6 |

6-8 |

|

Total Power (kw) |

37 | 55 | 75 | 90 | 110 |

| Moisture of Feeding Material | 20%-40% | 20%-40% | 20%-40% | 20%-40% |

20%-40% |

|

Size of Feeding Material(mesh) |

50 | 50 | 50 | 50 | 50 |

| Dimensions (mm) | 4100×1600×1150 | 4250×1850×1300 | 4700×2350×1600 | 4900×2550×1800 |

5500×2800×2000 |

Get Free Quote Now!