Fertilizer Production Process

With the rapid development of modern agriculture, the use of organic and compound fertilizer is becoming increasingly significant. Thus, many agricultural producers are interested in learning how to successfully transform organic and inorganic substances into high-quality fertilizers.

We will introduce the entire production process of organic and compound fertilizer, as well as the relevant equipment, and recommend excellent equipment for you.

Two Categories in Production of Organic Fertilizer

Organic fertilizer production equipment is to process raw materials rich in organic matter into organic fertilizer, such as livestock manure, sludge and garbage, filter mud from sugar mill, biogas residue and straw sawdust.

There are two major aspects of finished organic fertilizer: organic powder fertilizer and organic granular fertilizer.

1. Organic Powder Fertilizer Production Process

The whole process of organic power fertilizer production contains simple three processes: pre-treatment, primary fermentation and post-treatment.

Before composting, raw materials need to be treated and sieved to remove impurities. After they are transported to the yard, they are weighed and sent to the mixing device, where they are mixed with waste water and microbial agents.

Besides, the factories should adjust the moisture content, carbon and nitrogen ratio according to the raw materials’ composition and carry out the next process.

The mixed materials are sent into the fermentation site by the conveying machine.

You must adopt forced ventilation for oxygen supply, compost the pile every 2 days with the supply of certain water and nutrients, and control the fermentation temperature at 50℃-65℃ for aerobic fermentation.

This project has a fermentation cycle of 7-15 days. After the semi-finished products are discharged, they are ready to enter the next process.

Then you can send sieved materials to the dryer for drying.

Finally, the finished product is mixed with the addition of micro-nutrients in proportion to the amount of the organic matter and then packaged and stored for sale.

In conclusion, the complete process is as follows: Dehydration (fresh plants & manure) → Crushing → Screening → Mixing (e.g. microbial agent, livestock manure and straw mixed in certain proportion) → Composting & Fermentation → Adjusting temperature, forced draft and moisture content → Screening → Finished products → Packing → Storing

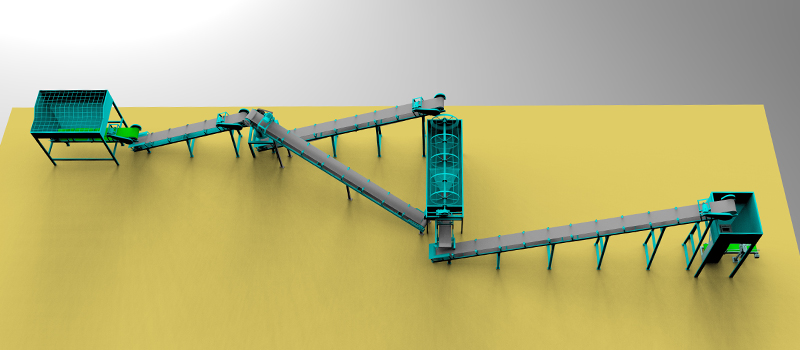

Organic Powder Fertilizer Equipment

The production of organic power fertilizer is relatively simple. The equipment includes five major units: organic fertilizer fermentation compost machine, the loader, feeder machine, crusher, and screening machine (rotary screener or vibrating screener). These machine need to connect with belt conveyors to form a complete production line.

2. The Frequently-used Organic Granular Fertilizer Production

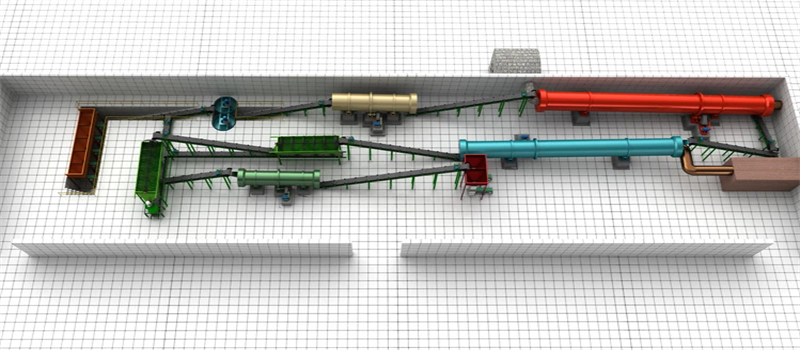

The entire organic granular fertilizer production process can be roughly divided into the following steps: Composting → Crushing → Mixing → Granulating → Drying → Cooling → Screening → Re-crushing → Coating → Packing.

Each production process requires the reasonable equipment to support, resulting in a balanced production system.

Organic Granular Fertilizer Production Process

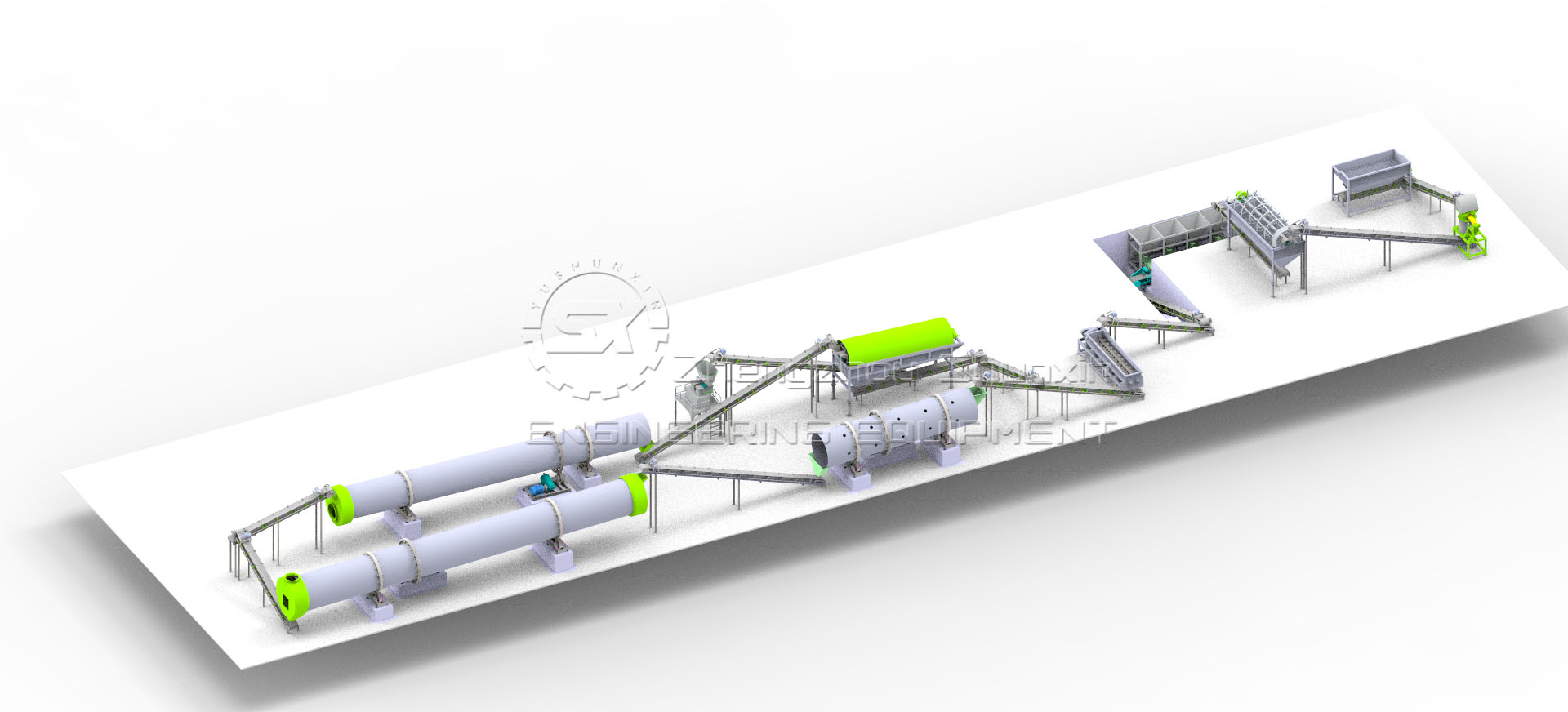

Organic Granular Fertilizer Equipment

Organic fertilizer production process is closely related to the layout of production line equipment.

Energy-efficient Compound Fertilizer Production

Our company offers the compound fertilizer production equipment with compact layout, scientific and reasonable design, and advanced technology. They have advantages of energy saving and consumption reduction, no environmental pollution, stable operation, reliable operation and convenient maintenance.

The equipment’s wide adaptability of raw materials make it applied frequently in compound fertilizer, pharmaceutical, chemical, feed and other industrial granulation, with a high granulation rate.

Compound Fertilizer Production Process

The process of compound fertilizer production can usually includes: Batching → Mixing → Granulating → Drying → Cooling → Screening → Re-granulating → Coating → Packing.

Compound Fertilizer Production Equipment

Compound fertilizer production equipment mainly includes:

- 1

Batching: Static batching machine and dynamic automatic batching system.

- 2

Mixing: Horizontal mixer, single shaft mixer, BB fertilizer mixer, disc mixer, etc.

- 3

Granulating: Rotary drum churning granulator, drum granulator, disc granulator and double roller extrusion granulator.

- 4

Auxiliary Equipment: Dryer and cooler, rotary screening machine, conveying machine, rotary coating machine, the automatic quantitative packing scale, automatic palletizer, etc.

The above is the detailed introduction of fertilizer production process.

Our company has focused on producing fertilizer processing equipment for many years, and we will develop a suitable production plan our customers’ actual demands to help them purchase the satisfactory equipment.

If you have any questions or needs, please do not hesitate to contact us, we will be delighted to serve you!

Get Free Quote Now!