Fertilizer Granulator Machine

Granulation is an important process for the production of granular fertilizers.

Moreover, granulation enhances powdered raw materials’ fluidity, appearance, and bulk density.

Granulators are also used in many fields, such as agriculture, animal feed, pharmaceuticals, chemical industry, etc.

What Are The Different Types of Fertilizer Granulator Machines?

We offer mainly seven different types of granulators, each with its own characteristics and applications, to fulfil the needs and budgets of various fertilizer production plants. For this, you can choose a suitable granulator based on its application, parameters and qualities.

1. New Type Organic Fertilizer Granulator

New type organic fertilizer granulator is capable of granulating a wide range of organic materials, particularly light granule powder materials. The processed particle shape is spherical, with a sphericity of about 0.7 and the granulating rate up to 90%. The particle size is generally between 0.3-3 mm.

We have five different specifications with capacities ranging from 1 to 8 tons per hour. The machine operates smoothly, is sturdy and durable, and it has a long service life. The majority of users regard it as the ideal equipment.

2. Rotary Drum Churning Granulator

Rotary drum churning granulator is optimal for combining organic and compound fertilizer. The combination of two granulation methods, wet stirring and rotary granulation, results in higher sphericity, more beautiful appearance and saving more energy than the drum granulator. We have one model SXZJZ-1660 with the capacity of 5-8t/h.

Extrusion granulator includes double roller extrusion granulator and flat die granulator.

3. Double Roller Extrusion Granulator

Double roller extrusion granulator is the key equipment of compound fertilizer granulation with advanced technology, low energy consumption, no return material and no drying and cooling processes. It can support the corresponding equipment, forming a small production line. The ball socket on the roller sheet mostly determines the shape and size of granules, and there is a large range of alternatives.

We offer three models: SXDG-1T, SXDG-1.5T, and SXDG-2T, and the finished product rate is over 95%.

4. Flat Die Granulator

Flat die granulator is mainly used for the granules processing of (biological) organic fertilizer and aquaculture processing industry. Before granulating, you do not need to dry and pulverize the raw materials, which saves a lot of energy.

We can configure a variety of molds to produce columnar particles with a diameter of 2-8mm. This machine processes the granular materials without return material have smooth surface, uniform shape, and can balance the internal nutrient content.

We have three different specification models (SXPM-400, SXPM-500, SXPM-600) with capacities ranging from 1 to 2.5 tons per hour, and the finished product rate is greater than 90%.

5. Disc Granulator

Disc granulator is suitable for organic fertilizer and compound fertilizer production. The granules made by the disc granulator are spherical, and the size is related to the angle of inclination of the disc and the amount of water added. The granulation rate can reach more than 93%. The equipment is intuitive to operate, low cost, smooth running, durable and has long service life.

However, its output is small, just 0.02-6t/h, so it is generally suitable for small organic fertilizer plants. Furthermore, because dust and exhaust gas can easily spilled and contaminate the environment, it may require additional auxiliary equipment.

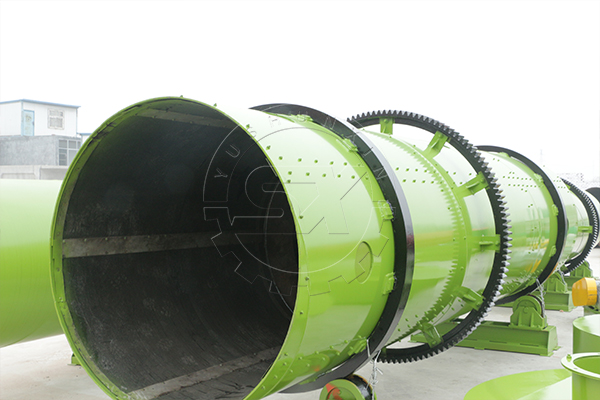

6. Rotary Drum Granulator

Rotary drum granulator is one of the key equipment in compound fertilizer industry. It is capable of producing high-medium-low concentration compound fertilizer on a large and medium scale. It has the greatest output capacity of all granulator, with specifications specifications of 1-30t/h, with no spillage of dust and exhaust gas, and automatic control devices for feeding and water spraying.

However, the pelletizing rate is low up to 70%. Some manufacturers additionally combine disc and drum granulators for secondary granulation to optimize the granulation effect.

7. Organic Fertilizer Polishing Machine

Organic fertilizer polishing machine is an ideal equipment for making spherical granules of organic fertilizer, which is suitable for polishing granules of organic and compound fertilizer. Its usage is on the basis of granulators.

And it is usually used to polish granules produced by the extrusion granulator and disc granulator, which makes pellets more beautiful and uniform size. We have a capacity of 1-8t/h with four different specifications, one-step forming, no return material, and the finished product rate of up to 95%.

Our factory is a professional fertilizer granulator manufacturer, to provide customers with good quality equipment, affordable price and considerate after-sales service.

If you are interested in our granulator equipment model, quotation and other details, welcome to contact our online customer service. The professional and technical staff free for you to design production plans, to ensure you can buy the most satisfactory machinery.

Get Free Quote Now!