Fertilizer Granulators

Two Granulation Methods

Dry Granulators

Dry granulation machine can manufacture products with relatively low material moisture, often less than 10%. It usually applies the extrusion technique to make pellets in variable shapes. Our plant has two types of dry granulators:flat die granulator & roller extrusion granulator, which needn’t carry out drying or crushing processes.

Flat Die Pellet Mill

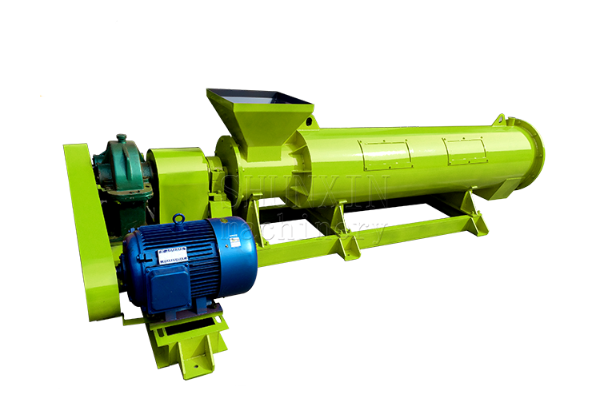

Dry Granulator for Organic Fertilizer ProductionDouble Roller Granulator

Dry Granulator for Compound Fertilizer ProductionDouble Roller Extrusion Granulator

Double roller granulator is a crucial equipment of compound fertilizer granulation, which has the advantages of advanced technology, compact structure and low energy consumption. It uses the extrusion principle to form fertilizer granules of 3-10mm in diameter at once.

Wet Granulators

Wet granulator is a device that mixes powdered or granular materials with a certain percentage of liquid, and then shapes and treats them to form pellets by the action of specific equipment and mechanical forces. Wet granulation refers to the production of pellets containing 20%-40% moisture. Furthermore, wet granulators have a variety of models.