There are a wide variety of packaging machines on the market today, suitable for different industries and product types. In the field of agriculture and fertilizer production, the choice of packaging machine is crucial for production efficiency and quality. Meanwhile, many customer care about how much is bagging machine.

Our company, Shunxin, with above 15 years of production and research experience, is a professional equipment manufacturer dedicated to providing high quality and efficient agricultural packaging machines. We mainly perform three types of bagging machine: automatic packing scale, automatic palletizer and automatic filling machine.

What Is The Cost of The Packing Machines?

We know most fertilizer plants and other industries care about the packaging equipment’s prices in different types. There are several aspects of factors affecting the bagging machines’ costs as follows.

1. What Is The Influence of Raw Materials’ Properties on Packing Machines’ Price?

2.What Is The Impact of Capacity on Packing Machines’ Price?

Reference of Automatic Packing Scale

- Packaging Material: Plastic/Woven bag

- Production Capacity: 6 bags/min; 7 bags/min

- Power: 2.2kw

- Packing Weight Range: 10-50kg/bag

- Packing Speed: 10-12s/bag

- Permissible Error: ±1%

- Including: Belt Conveyor & Sewing Machine

What Are The Prices of Automatic Bagging Machines?

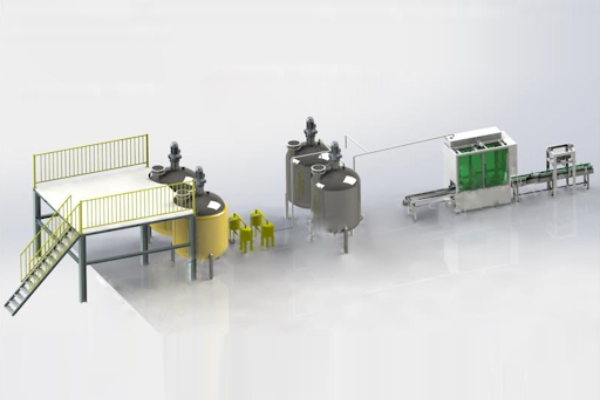

Moreover, automatic filling machine can process liquid fertilizers with the capacity of 5,000-100,000 L/day. If you choose to purchase the complete set of equipment for the liquid fertilizer production line, we will give you an appropriate discount. The price of a common liquid fertilizer production line is around $20,000.

To some extent, automatic palletizer can also save money. It can form a automatic bagging production line with the packing scale for weighing, packaging, sewing, transportation and stockpiling. Therefore, it is the most suitable for commercial fertilizer production. The larger the organization is, the more obvious the economy returns will be and the greater the benefits to the company.

Robot palletizer has become vital equipment, particularly in chemical fertilizer, feed, light, medicine, food, daily chemical and other industries. What’s more, it needs large investment, nearly 10,000-15,000 dollars, with the capacity of 30-60 boxes/min. It plays an important role in shortening the production cycle, reducing worker labor intensity, and increasing production and work efficiency.

3. What Is The Affect of Materials on Packing Machines’ Price?

More importantly, the manufacturing materials and the level of technology of the packing machine directly affect the price. SX automatic bagging equipment usually applies high-quality and durable materials, which has a longer service life and better performance.

For instance, the automatic packing scale and the robotic palletizer are of 304 stainless steel materials, aluminum or carbon steel body frame. Thus, the service life is generally two times higher than that of similar products. Furthermore, the entire body of the automatic filling machine almost entirely consists of stainless steel, which is wear-resistant and corrosion-resistant, so the price will be slightly higher.

4. What Is The Effect of Automation Degree on Packing Machines’ Price?

The degree of automation and additional functions of the packaging machine are also have an impact on the price. Fully automatic machines can usually reduce labor requirements and improve production efficiency, but their prices are relatively high.

In general, for inadequate budgets or small production scale, most fertilizer manufacturers choose semi-automatic packaging machinery, since fully automatic packaging machine is more expensive than the former. Using semi-automatic packaging machine can save investment costs. And the operation is very simple — only 1-2 workers assist in bagging and conveying to the next step.

Our equipment also has automatic control systems and precision sensors, which can improve the accuracy and stability of packaging processes. In addition, it also has some additional functions, such as automatic weighing system, fault detection and alarm system, to ensure the safety of the production process. While choosing to purchase devices, you need to consider in accordance with actual production requirements.

As a result, the choice of bagging machine depends on various factors such as the type of fertilizer being packaged, production output, level of automation, and budget constraints. Our customers select the most appropriate type among the bagging machines based on their specific needs and operational requirements. We offer a one-year warranty service to replace damaged parts for free. Welcome to contact us for free quotation!